The Most Reliable Desktop Screw Feeder for Global Production

Maintenance-Free Design. No Specialist Needed. Built for Independent Operation.

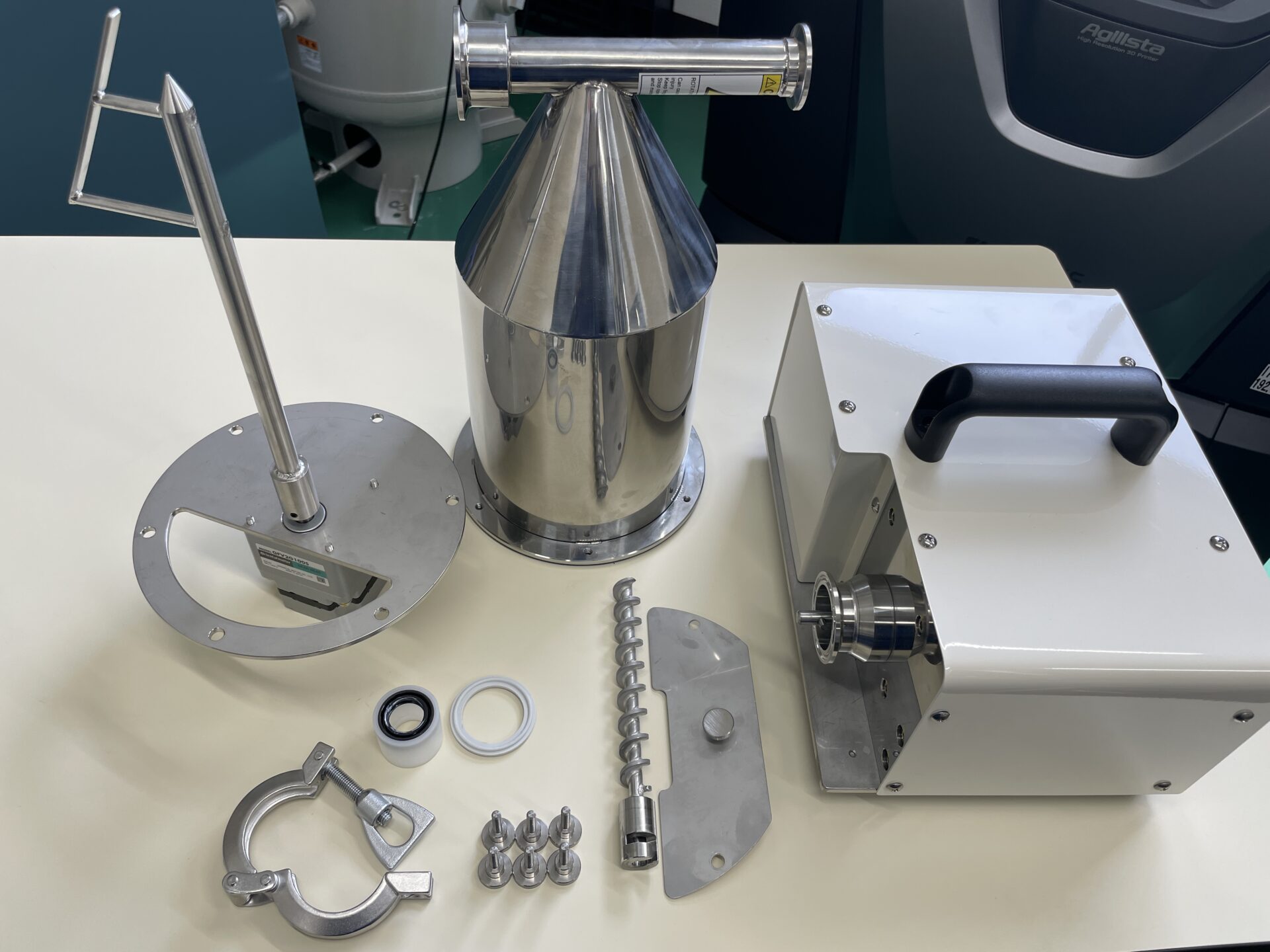

Watch how simple it is: Tool-free disassembly in under 30 seconds!

Minimal Moving Parts

We have physically eliminated common failure points by streamlining the internal mechanism. Fewer moving parts mean less wear, ensuring long-term stability without the need for periodic adjustments.

High-Grade Japanese Components

Every unit is engineered and manufactured in Japan using premium, wear-resistant materials. Our strict quality control guarantees a “set-and-forget” experience even in demanding environments.

100% Tool-Free Interface

No specialized tools or local technicians are required. Our intuitive design allows any operator to disassemble and clean the unit in seconds, eliminating dependency on external support.

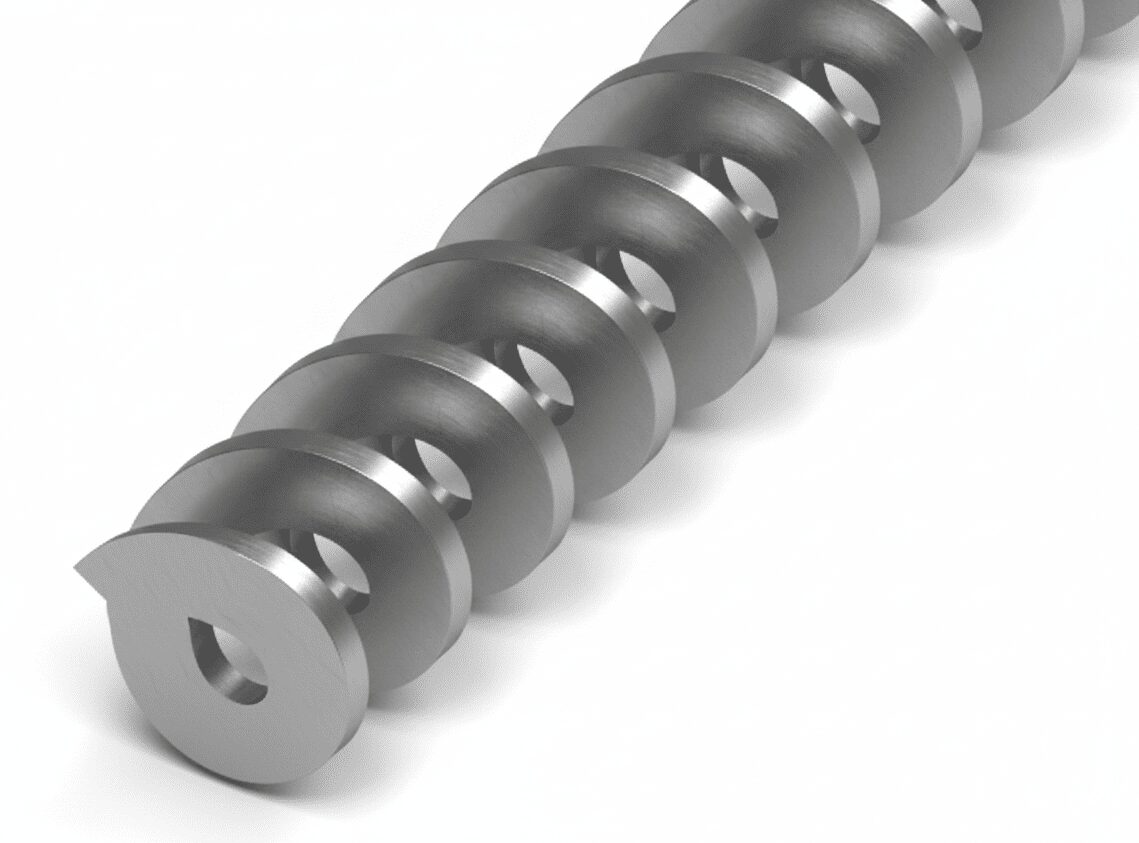

4 Screw Types for Every Need

1.Standard screw(Most Versatile)Ideal for a wide range of materials.

2. Double-Start (High Precision) Best for stable, small-volume output.

3. Coreless (Anti-Clogging) Ideal for sticky or adhesive materials.

4. Spring (Anti-Jamming) Best for pellets and granular materials.

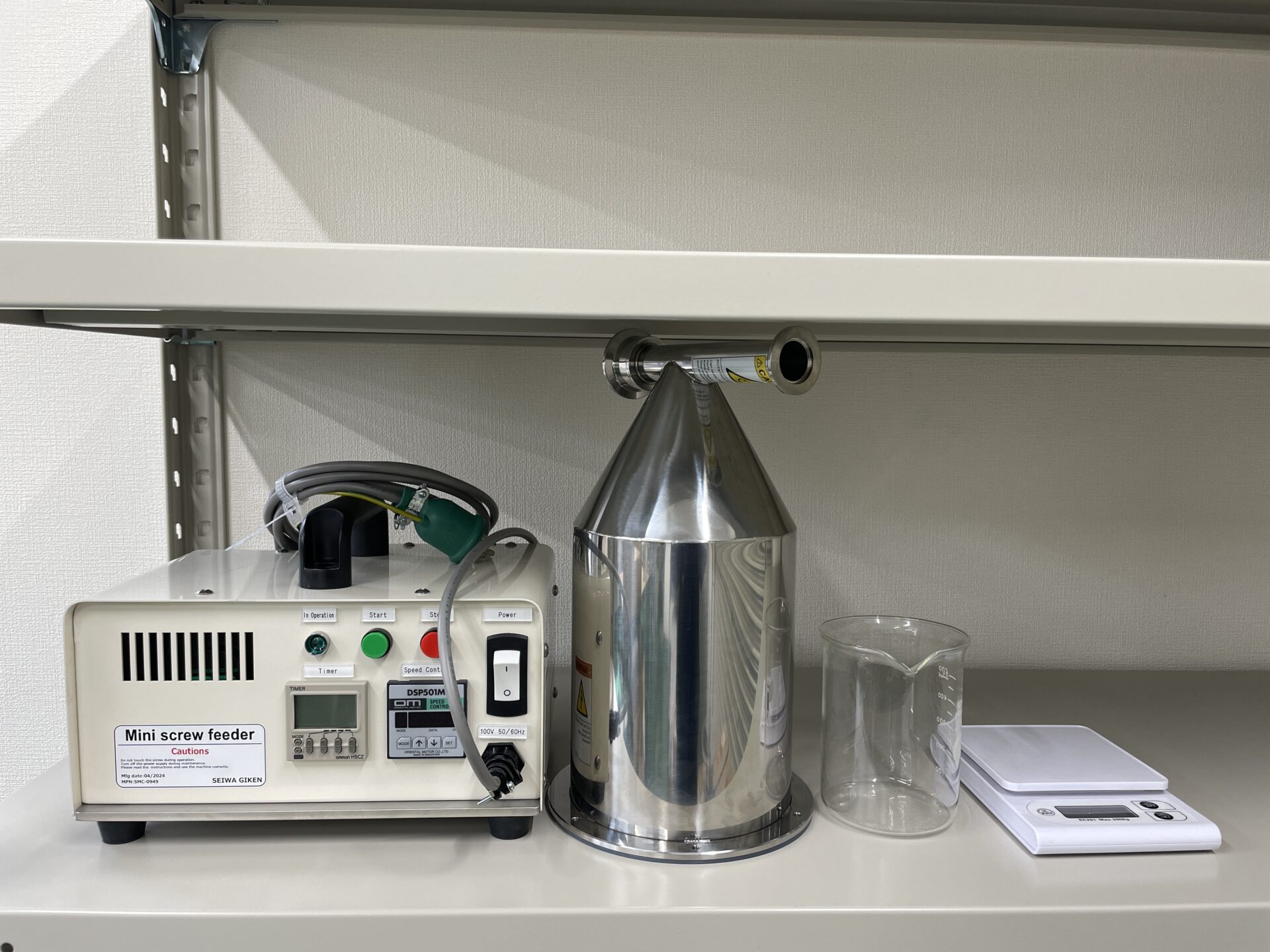

| Specification | Speed control and Timer |

|---|---|

| Feeder diameter | φ25.4 |

| Feed Screw | Standard, shaftless,Double-start,and Spring |

| Hopper capacity | 1L.or 3L |

| Feed rate | (Standard) 600g-6kg / hour ※In case of pellet(Bulk density:0.7) (High speed H) 1200-12Kg / hour (Low speed L) 300 ~ 3Kg / hour (Ultra low speed SL) 60-600g / hour |

| Timer | Digital timer (up to 99 minutes 59 seconds) |

| Input voltage | Single phase 100V AC(50/60hz) |

| External dimensions | (W)150×(D)437×(H)406mm ※For standard model |

Solution Options for Specific Requirements

Agitator model

Anti-Bridging: Best for sticky or fine powders. Internal blades ensure consistent material flow into the screw.

Vibrator model

Contamination Control: External vibration assists flow without internal contact, ideal for high-purity applications.

Customized model

Custom Integration: Custom pressure-resistant housings, ferrule welding, and tailored interface connections.

Proven Performance: Feed Rates by Material Density

Estimated Feeding Capacity

The following data represents typical feed rates based on material density. Actual capacity may vary depending on material flowability.

| Material Category | Bulk Density | Max Feed Rate | Characteristics |

|---|---|---|---|

| Carbon Powder | 0.16g/cm³ | 2.0 kg/h | Ultra-light / High bridging risk |

| Slaked Lime (Hydrated Lime) | 0.50g/cm³ | 3.0 kg/h | Fine powder / Cohesive |

| Iron Powder | 3.00g/cm³ | 17.0 kg/h | High density / Free-flowing |

*Note: These values are for reference only. We recommend a feeding test with your actual material for precise calibration.

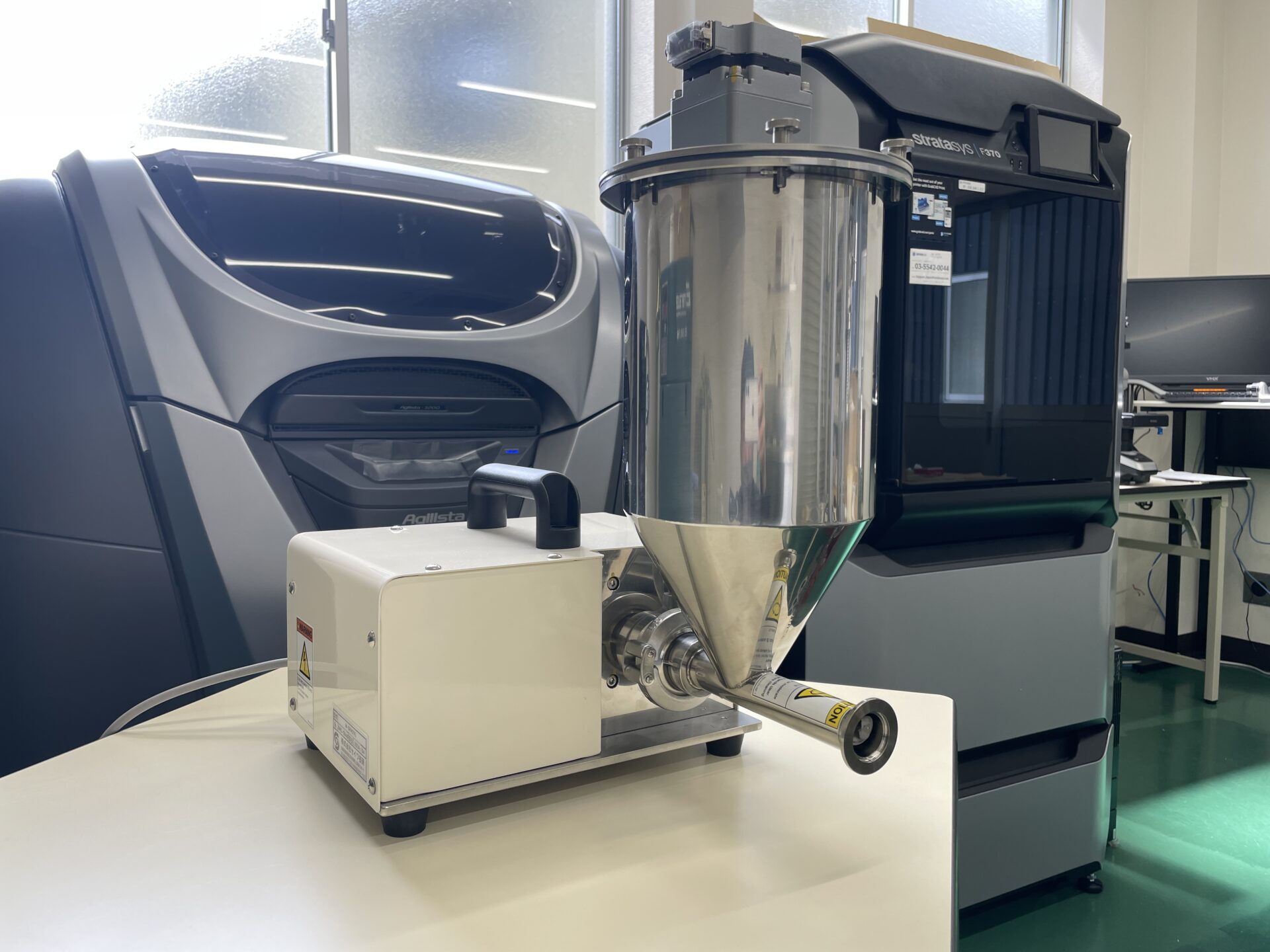

Used as science and laboratory equipment

Our mini screw feeders are chosen as one of the tools for experiments, research, and development. For example, they are very useful when you want to feed a certain amount in a laboratory, or when you want to test various raw materials little by little in product development. No tools are required for disassembly, and cleaning and sterilization can be completed in a short time. Since it can be installed on a desktop, it is possible to change its location as needed. Having one in your lab is sure to make your projects run more smoothly.