1.Overview

The supply of powder materials to the next process is a crucial step that directly impacts product quality stability. However, in many manufacturing sites, issues such as product defects and inconsistencies arise due to unstable supply caused by manual feeding or the use of inappropriate feeders. One of the best solutions to these problems is the introduction of a screw feeder. Below, we explain key points to consider when selecting a screw feeder.

2.Challenges in Powder Supply

Unstable supply due to manual feeding

- Use of feeders that do not match the powder’s characteristics (e.g., vibratory feeders)

- Selection of feeders with inappropriate sizes (e.g., feeders that are too large for the required supply volume)

These problems lead to variations in product quality and decreased production efficiency, significantly affecting a company’s competitiveness.

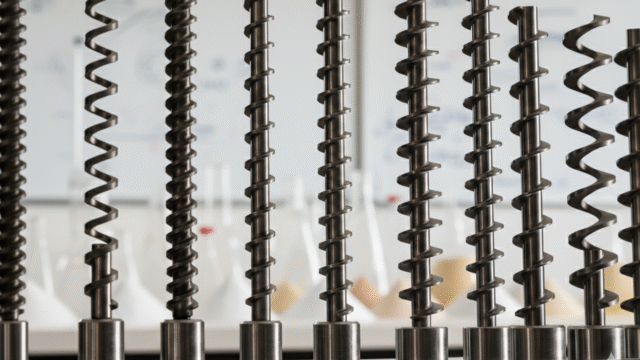

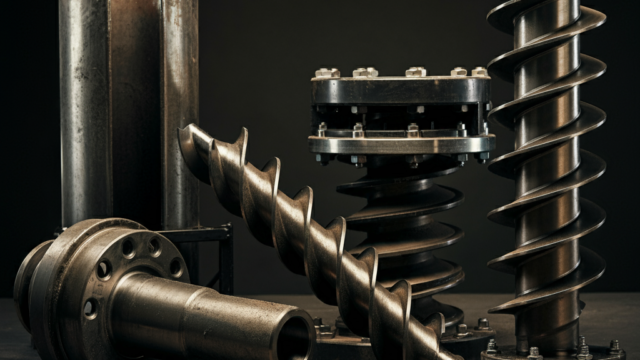

3.Solution: Introducing an Appropriate Screw Feeder

The optimal solution to these issues is introducing a screw feeder capable of handling the specific characteristics of the powder and providing precise feeding that matches the required supply volume. However, there are several important points to consider when selecting a screw feeder.

4.Five Key Points for Selecting a Screw Feeder

- Choosing a Manufacturer with Powder Knowledge

It’s essential to choose a screw feeder from a manufacturer that understands the characteristics of powders. A manufacturer experienced in powders can propose effective solutions when problems occur.

Can they suggest solutions based on past issues? Can they run tests to reproduce potential issues? - Customization for Existing Equipment

If the feeder is being retrofitted, choose a manufacturer that can offer customization to match your existing equipment.

Check if flexible design changes, such as feeder length, size variations, hopper capacity, and control methods (inverter capacity control, load cell weighing control, etc.), are possible. - Cost-Effective Customization

Customizing a standard product can help keep costs low.

Highly expensive feeders may offer excessive performance, so it’s important to balance the intended use and precision.

Avoid selecting completely custom-designed products and opt for cost-effective solutions.

However, if you need equipment that exactly matches your existing setup, selecting a manufacturer that can faithfully reproduce the same design may be necessary. - Availability of Spare Parts

Choose a feeder that uses mainly standard parts in areas prone to trouble.

The ease of obtaining spare parts will shorten maintenance time and reduce costs. - Short Delivery Time for Parts

The short lead time for ordering fabricated parts is also an important factor.

Be cautious with large-scale manufacturers that may take longer to deliver and offer less flexibility.

Quick delivery of parts contributes to minimizing downtime.

5.Conclusion

Selecting the appropriate screw feeder ensures stable powder material supply, improves product quality, and enhances production efficiency. By considering the five points mentioned above, you can choose the optimal screw feeder.

6.What Can SEIWA GIKEN offer?

Our company strives to meet the above requirements by providing various flexible solutions. With years of experience in powder handling, we offer customized solutions tailored to different customer needs and installation sites, and provide swift responses through in-house manufacturing. We deeply understand the challenges posed by problematic powder characteristics, and we offer solutions that address compatibility with existing equipment, cost efficiency, spare part availability, and shorter lead times through in-house processing. As a powder equipment manufacturer, we not only manufacture products but also provide comprehensive solutions to help resolve powder supply challenges. Please utilize our knowledge and technology to address your powder supply issues.