Preventing Dust Explosions in Powder Feeding Systems with Screw Feeders

Dust explosions are a serious hazard in many industries that handle fine powder materials. Whether you’re working in chemical processing, pharmaceuticals, food manufacturing, or battery production, managing the risk of explosion is essential. One critical aspect of explosion prevention lies in the design and operation of your powder feeding system, especially if you’re using a screw feeder.

What Causes a Dust Explosion?

A dust explosion can occur when fine particles become suspended in the air and are exposed to an ignition source. In enclosed environments, this can result in rapid combustion that generates pressure and heat—potentially leading to catastrophic damage. Common ignition sources include static electricity, friction heat, or mechanical sparks from equipment such as feeders, mixers, or conveyors.

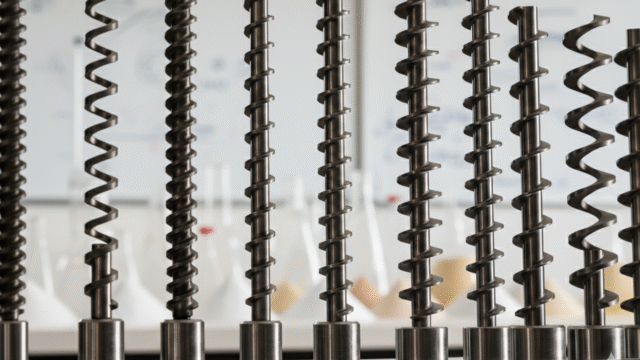

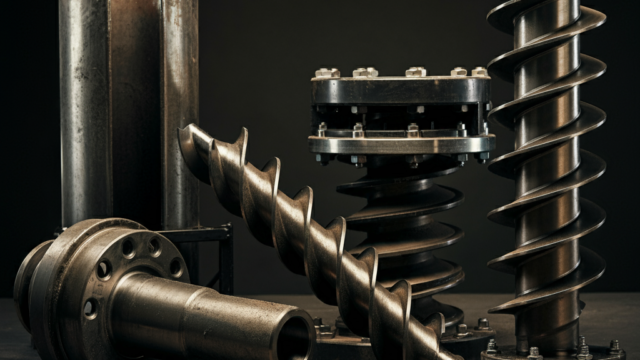

The Role of Screw Feeders in Dust Explosion Prevention

A screw feeder is a common choice for accurate powder feeding in industrial processes. However, if not properly designed, it can become a source of ignition. Friction between powder particles and rotating metal components, especially in continuous operation, may generate localized heat. If the powder being fed is combustible, such as resin, starch, or fine organic materials, the risk of ignition increases.

To prevent such incidents, it’s important to design your screw feeder with dust explosion safety in mind:

- Use of Non-sparking Materials: Consider using materials like stainless steel or specially coated metals that reduce the chance of spark generation.

- Proper Grounding: Static electricity can build up inside a powder feeding system. All equipment should be properly grounded to safely discharge any buildup.

- Speed Control: Feeding speed should be optimized to avoid overheating due to excessive friction or motor load.

- Monitoring Temperature and Vibration: Advanced powder feeding systems often include sensors to detect abnormal conditions early.

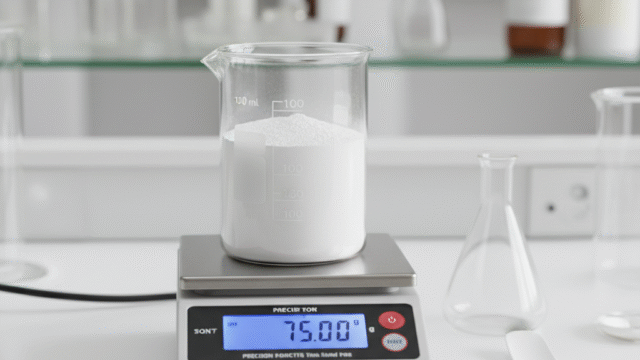

Consider the Characteristics of Your Powder

Not all powders pose the same risk. Fine, dry powders with low moisture content and high surface area are generally more prone to dust explosions. If your process involves materials such as flour, carbon black, metal powder, or chemical dust, additional precautions should be taken.

When selecting a screw feeder for these materials, discuss the explosion risk with your equipment provider. Some screw feeders are available with optional features such as nitrogen purge lines, flame arrestors, or explosion-proof motors.

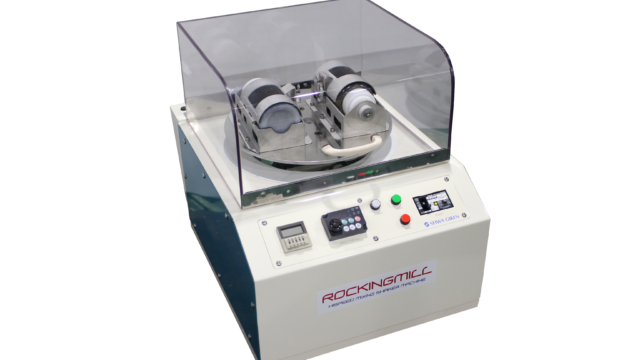

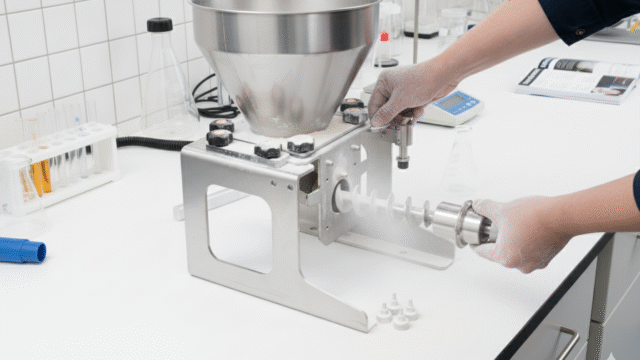

Compact and Safe Powder Feeding Solutions

At Seiwa Giken, we specialize in designing compact screw feeders that deliver precise powder feeding while considering safety and usability. Our feeders are ideal for labs and production lines requiring accurate, small-quantity feeding of various powders.

Our latest models prioritize safety, with design features that reduce friction and static, and enable easy cleaning and maintenance. If you are handling combustible powders, our team can help you choose the right configuration to minimize risk.

Conclusion

Dust explosions remain a hidden danger in many powder-handling processes. Choosing the right screw feeder and designing your powder feeding system with safety in mind can greatly reduce this risk. If you’re looking for compact, customizable, and explosion-conscious feeding solutions, we’d be happy to support your process.