How to Introduce Powder Feeders That Fit into Compact Factory Spaces

In recent years, the effective use of space in manufacturing has become an increasingly important issue. Especially in urban factories and production facilities with limited space, efficient equipment layout and operation are essential. In this context, space-saving screw feeders have become an ideal choice for many companies. This article will explain the benefits of space-saving screw feeders and provide examples of their implementation.

Benefits of Space-Saving Design

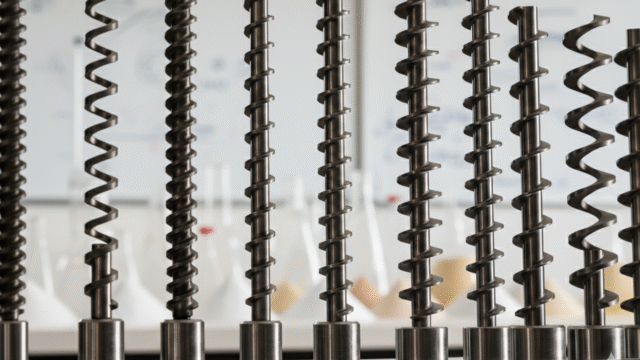

Maximizing operational efficiency in compact factory spaces requires downsizing equipment. Conventional large-scale feeders take up a lot of space, often limiting the flexibility of production line design. However, the compact design of space-saving screw feeders allows them to be easily installed and operated even in restricted spaces.

Additionally, screw feeders provide efficient powder feeding while minimizing the overall footprint of the equipment, reducing interference with other machinery. As a result, factory productivity improves, and the layout becomes more flexible, allowing for future expansion or changes to the production line.

Cost Efficiency of Implementation

Reducing space also leads to cost savings. Compact screw feeders lower installation and wiring costs, reducing the overall initial investment. Furthermore, their small size makes maintenance easier, reducing the time and cost required for regular inspections.

Screw feeders are particularly durable, allowing for stable operation over long periods. This helps minimize downtime due to equipment stoppages, thus improving overall cost efficiency. From a long-term perspective, reduced operating costs provide significant benefits to companies.

Case Study 1: Urban Pharmaceutical Factory

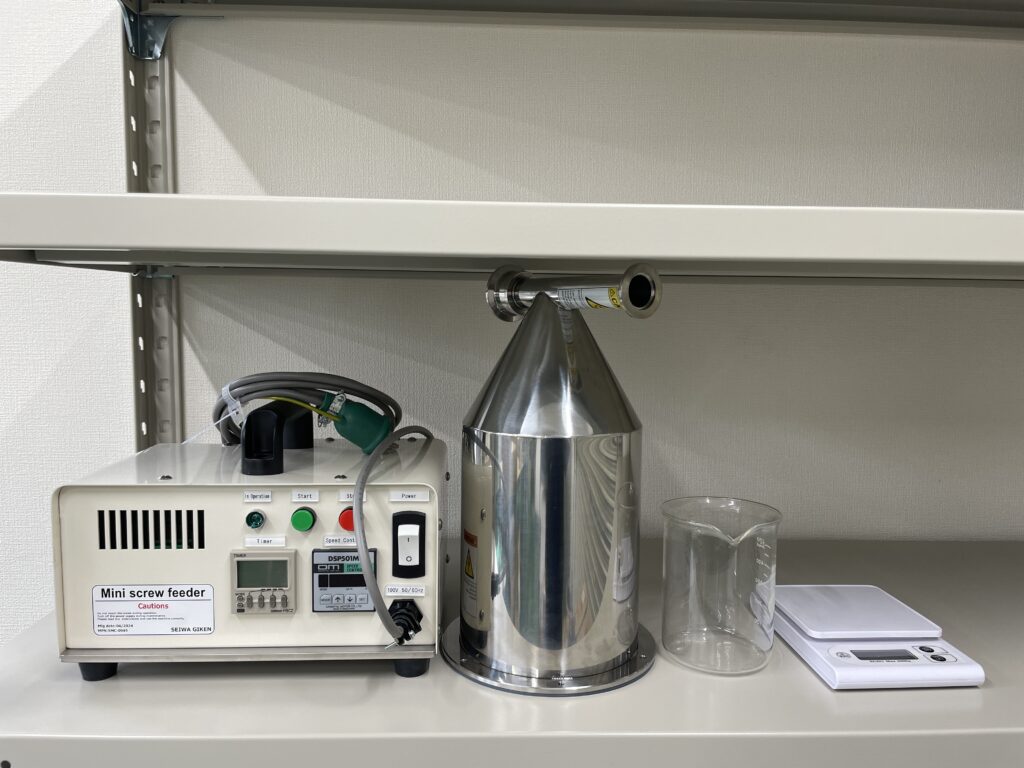

An urban pharmaceutical factory introduced compact screw feeders to maximize the use of limited space. The factory frequently needed to supply different types of powders, but the space-saving design allowed multiple feeders to operate simultaneously.

These feeders are equipped with advanced control systems that automate the mixing and adjusting of powder supply amounts. This not only reduced the workload for workers but also improved productivity by about 20%. Additionally, the simple maintenance of the feeders significantly reduced downtime.

Case Study 2: Application in a Food Factory

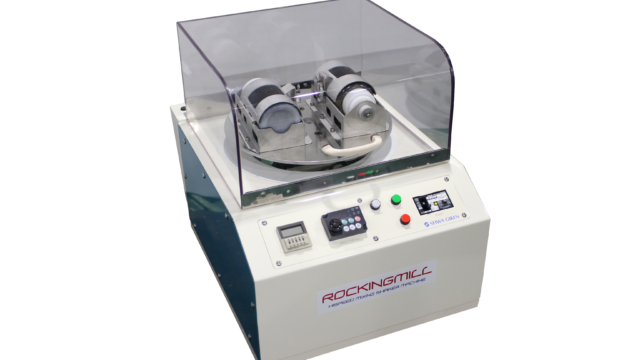

In a food factory with strict quality control standards, many machines needed to be placed in a small space. The space-saving screw feeders introduced there ensured uniform powder feeding and stable operation on a fast production line. As a result, the factory’s production efficiency improved significantly, and product quality also increased.

These screw feeders were designed for easy cleaning, earning high marks for hygiene. Hygiene is a critical factor in the food industry, which was a decisive factor for the introduction. Furthermore, the space-saving design minimized interference with other machinery, adding great flexibility to the overall factory layout.

Future Outlook

The demand for space-saving screw feeders is expected to continue growing across various industries. Especially in urban and space-constrained factories, the effective use of space will become increasingly important, and the need for compact, efficient feeding equipment will rise.

In addition to space-saving designs, there is likely to be progress in improving energy efficiency to reduce environmental impact and introducing more advanced automation technologies. This will lead to increased adoption of screw feeders in more factories, contributing to improved production efficiency.

Conclusion

Space-saving screw feeders that fit into compact factory spaces are essential tools for maximizing limited space and improving production efficiency. Considering their cost-effectiveness in terms of both initial and operational costs, as well as the successful case studies, it is expected that their use will continue to expand across various industries.