In manufacturing, precise formulation management of raw materials is essential to ensure product quality. Especially in processes involving powder handling, even slight discrepancies in formulation can significantly affect product performance and quality. To address these challenges, precision dosing systems using screw feeders have garnered attention. This article explains how to achieve precise formulation management using screw feeders.

1.Mechanism of Screw Feeders and the Necessity for Precision Formulation

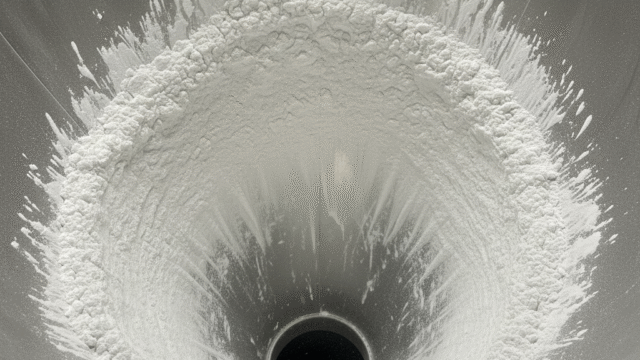

A screw feeder is a device that quantitatively feeds powders and granules by rotating a spiral-shaped screw. Since it provides a stable and controlled supply of powders in fixed quantities, it is ideal for material feeding in manufacturing lines. Especially in processes requiring precise blending of multiple raw materials, it is critical to mix each component in exact proportions. Even the slightest error can alter product properties and lead to inconsistent quality

For instance, in industries such as chemicals, food, and pharmaceuticals, it is essential to mix raw materials with milligram-level precision. Screw feeders play a vital role in achieving such high-precision formulations.

2.Features of Screw Feeders Enabling High-Precision Formulation

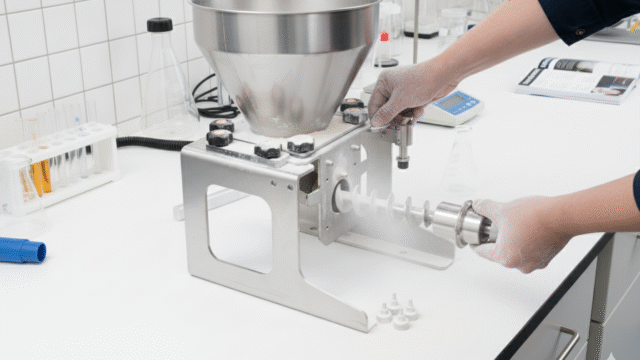

Screw feeders can deliver powders with extreme accuracy due to their structure and functionality. By optimizing the shape and pitch (the distance between the screw threads), the feed rate can be adjusted according to the flowability or viscosity of the powder. Additionally, when combined with weight sensors or flow sensors, the feed amount can be monitored in real-time, allowing for feedback control as needed.

Moreover, screw feeders are resistant to external influences such as vibration, ensuring high feed stability. This makes it possible to maintain a stable feed even in environments where powder flowability changes due to temperature or humidity variations. By implementing a high-precision feedback system, formulation errors can be minimized to the milligram level, ensuring consistent product quality.

3.Automated Formulation Process for Consistent Quality Control

One of the major advantages of screw feeders is the ability to automate the formulation process. Processes that traditionally required manual weighing and feeding can now be automated, eliminating human errors and ensuring consistent quality control. This is particularly important in industries such as pharmaceuticals and food, where formulation errors directly impact product safety, making the introduction of an automated precision feeding system crucial.

Furthermore, the efficiency gained through automation cannot be overlooked. In production environments where frequent recipe changes are required, such as small-batch production, screw feeders allow for easy adjustments of blending ratios by simply entering the recipe settings into the system. This reduces switchover time between production lines and improves operational efficiency.

4.Key Points When Implementing Screw Feeders

To achieve precise formulation management, selecting the right screw feeder is crucial. The screw shape and material must be chosen according to the characteristics of the powder being supplied. For example, standard screws are suitable for powders with high flowability, while special coatings may be needed for highly viscous powders or powders sensitive to humidity.

For controlling the feed amount, it is effective to implement a system combining weight sensors or flow meters. This enables real-time monitoring of the feed amount, minimizing errors. Additionally, in industries where formulation mistakes are unacceptable, a redundant dual-control system can be adopted to ensure even greater safety.

5.Conclusion

In manufacturing processes requiring precise formulations, the implementation of screw feeders proves to be highly effective. High-precision feed control and automation not only allow for consistent product quality but also contribute to improving production efficiency and reducing costs. By selecting and implementing the most suitable screw feeder for the specific characteristics and needs of the factory, challenges related to precision formulation can be addressed, leading to further quality improvements.