In factory operations, ensuring the stable supply of powders of varying sizes can be a challenging task. Since the particle size of powders can differ depending on the product, it is essential to have a flexible system that can efficiently supply these materials. This article explains how to choose a screw feeder that can handle various powder sizes.

1.Characteristics of Powders and the Challenges of Supply

When the size of powders differs, so do their properties, such as flowability and cohesiveness. Fine powders tend to absorb moisture and clump together, while larger particle powders flow more smoothly but can be difficult to supply uniformly. Factories that handle powders of different particle sizes often need to use the same equipment for multiple types of powders, requiring a flexible supply system.

2.Key Points for Screw Feeders That Handle Various Powders

When dealing with powders of different sizes, the screw feeder’s ability to adapt flexibly depends on several factors. By focusing on the following points, efficient supply can be achieved:

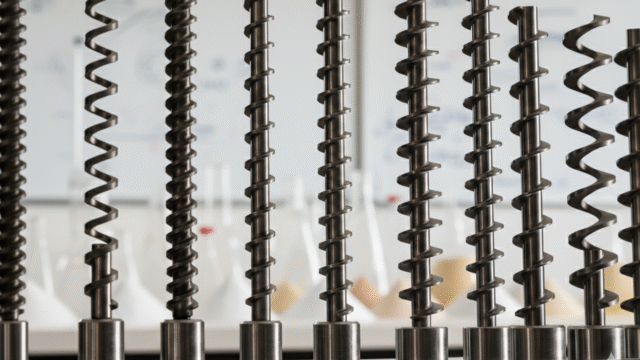

3.Screw Design Selection

The design of the screw in the screw feeder greatly affects powder flow. The optimal screw design differs for fine and large-particle powders. For fine powders, screws with narrow pitches or those with stirring effects are suitable, allowing for the smooth flow of materials prone to clumping. On the other hand, for large-particle powders, screws with wider pitches or designs that promote flow are effective. For handling multiple types of powders, a feeder that allows switching between different screw designs is ideal.

4.Variable Speed Adjustment Function

The ability to adjust the supply speed according to the size of the powder is also crucial. Large-particle powders can be supplied relatively quickly, but fine powders require a slower, more careful supply. A screw feeder with a variable speed function can be adjusted to the appropriate supply speed based on the powder size, improving accuracy.

5.Powder Density Control

In powder supply, not only particle size but also powder density affects supply accuracy. Keeping the powder density consistent during supply leads to more stable operations. This reduces fluctuations in the supply volume even when dealing with powders of varying particle sizes, ensuring a stable production process.

6.Advantages of Modular Screw Feeders

One approach to handling a variety of powder sizes is the use of modular screw feeders. Modular feeders allow for the easy replacement of screws and feed tubes, enabling flexible responses based on the type of powder. This not only facilitates the efficient supply of powders with different particle sizes and properties but also reduces changeover time in production lines.

7.Choosing with Maintenance in Mind

Screw feeders must not only handle various powders but also be easy to maintain. When dealing with powders of different sizes, residue and clogging inside the feeder can be common issues. Selecting a screw feeder with a simple internal structure and easy cleaning can reduce daily maintenance efforts and minimize downtime.

8.Conclusion

In factories that use powders of different sizes, screw feeders must be flexible enough to adapt. By considering screw design, speed adjustment, density control, modularity, and ease of maintenance, a stable supply of various powders can be achieved. Choosing the right equipment can lead to improved productivity and cost savings.