1. Overview of Small High-Speed Powder and Liquid Mixers

Small high-speed powder and liquid mixers are designed to quickly and uniformly mix powders and liquids. These mixers are widely used across various industries, including food, pharmaceuticals, and chemicals. Despite their compact size, they offer high efficiency, saving space and making installation easier compared to traditional larger machines. They are also user-friendly and capable of efficiently handling small to medium batches, making them ideal for small-scale production lines and research and development applications.

2. Features of Small High-Speed Mixersview of Small High-Speed Powder and Liquid Mixers

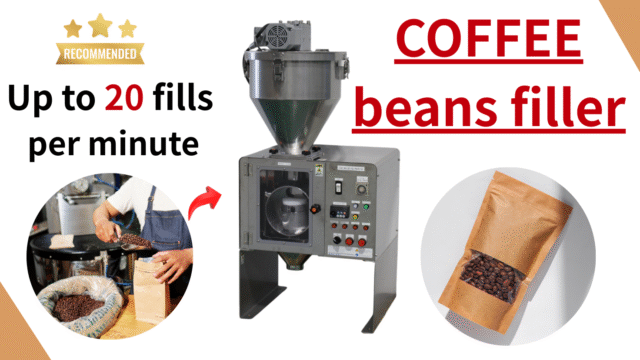

The key feature of small high-speed powder and liquid mixers is their outstanding mixing performance achieved through high-speed rotation. This rapid rotation allows for uniform mixing of powders and liquids in a short time, helping to stabilize product quality. The mixers prevent powder agglomeration and can evenly disperse fine particles. Depending on the mixing tank design, they can efficiently handle high-viscosity liquids, making them suitable for a wide range of materials.

3. Benefits and Applications of Small Mixers

Small high-speed mixers are valued for their versatility and ease of use, finding applications across various fields. In the pharmaceutical industry, they are suitable for mixing powdered drugs and supplements, while in the cosmetics industry, they are used for producing creams and lotions. Additionally, in the chemical industry, they are often employed for the preparation of adhesives, paints, and inks. This versatility in handling diverse products is a significant advantage.

4. Technological Advances and Improved Mixing Efficiency

Recent technological advances have further improved the mixing efficiency of small high-speed powder and liquid mixers. The latest models come equipped with high-precision sensors and automated control systems, allowing real-time monitoring of the mixing process. This enables optimization of mixing time and prevention of overmixing, contributing to energy savings. Additionally, innovations in the shape and arrangement of stirring blades help minimize inconsistencies in the mixture of powders and liquids.

5. Ease of Cleaning and Maintenance

Another advantage of small mixers is their high level of cleanability. Many designs feature detachable mixing tanks and stirring blades, enabling quick and easy cleaning. This is a crucial factor in enhancing the efficiency of production lines. Moreover, the simple structure with fewer parts facilitates easy routine maintenance, reducing operational costs. The ease of cleaning is especially beneficial in industries such as pharmaceuticals and food, where stringent hygiene standards are required.

6. Demand for Small High-Speed Powder and Liquid Mixers in Overseas Markets

Small high-speed mixers are also in high demand in overseas markets. In North America and Europe, where strict quality control is required in food and pharmaceutical manufacturing processes, compact and high-performance mixers are highly valued. In Asia, the growing manufacturing sector is driving demand for efficient and cost-effective small mixers. The overseas demand for these mixers is expected to continue expanding.

7. Future Outlook for Small High-Speed Powder and Liquid Mixers

In the future, small mixers with even higher performance and energy efficiency are expected to be developed. The introduction of automation technology and AI will further enhance the efficiency of the mixing process. Additionally, the use of IoT for data collection and analysis will enable real-time process management and predictive maintenance, leading to improved productivity and cost reduction.

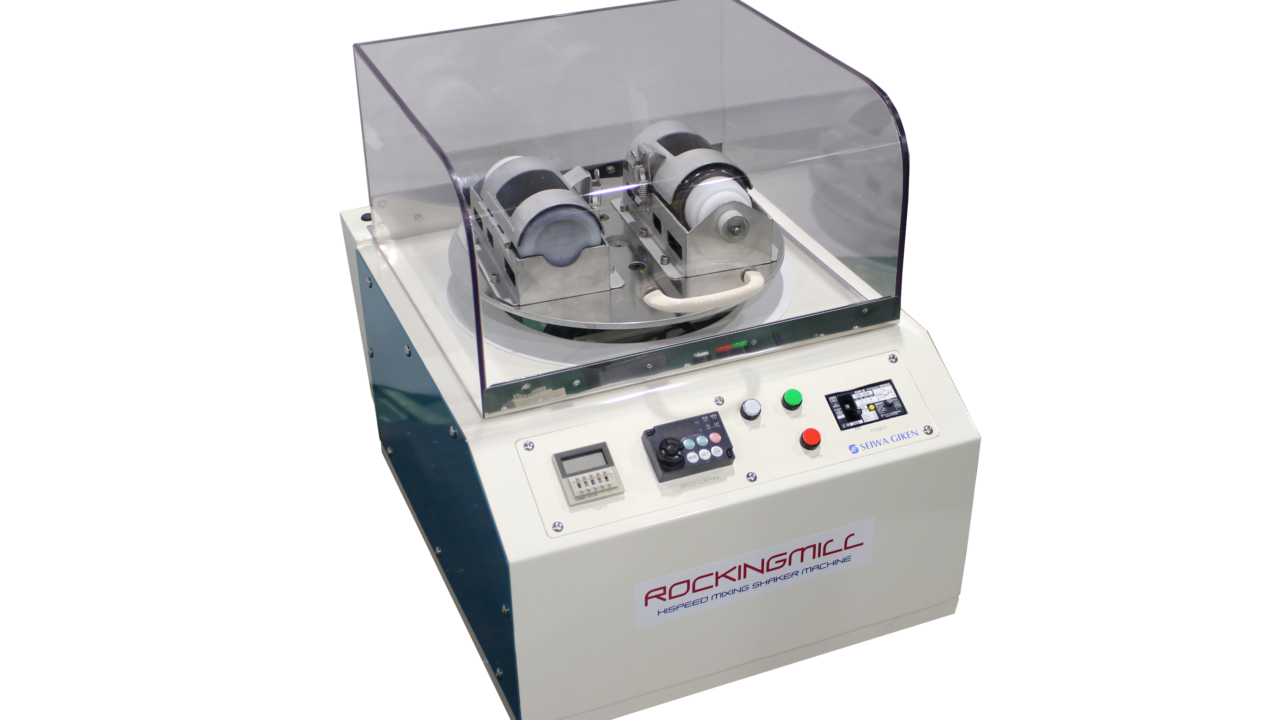

8. Seiwa Giken’s Popular “Rocking Mill“

At Seiwa Giken, the high-speed locking mill mixer is very popular. This container-type mixer operates without blades, preventing damage to raw materials. It can accommodate commercially available containers, streamlining pre- and post-testing processes, and is widely used by companies and research institutions in various fields, both domestically and internationally.

9.Conclusion

Small high-speed powder and liquid mixers offer versatility and high performance, making them widely used in industries such as food, pharmaceuticals, and chemicals. Their ability to provide uniform quality through high-speed mixing, ease of cleaning, and simple maintenance makes them especially valuable in fields where hygiene is crucial. With technological advancements, further improvements in efficiency and energy savings are anticipated, and strong demand in overseas markets is expected to continue.