What is the Angle of Repose of Powders?

The angle of repose of powders refers to the angle formed by the conical slope that naturally occurs when the powder is piled onto a flat surface. This angle is influenced by factors such as the powder’s flowability, particle shape, moisture, and surface friction, making it an important indicator in the handling, storage, and transportation of powders. Generally, the smaller the angle of repose, the higher the powder’s flowability, while a larger angle indicates that the powder is more cohesive and less likely to flow.

Measuring the angle of repose is a common practice in powder engineering to understand the characteristics of the powder and ensure efficient transport and handling. Let’s consider why the angle of repose is important when selecting a powder feeder.

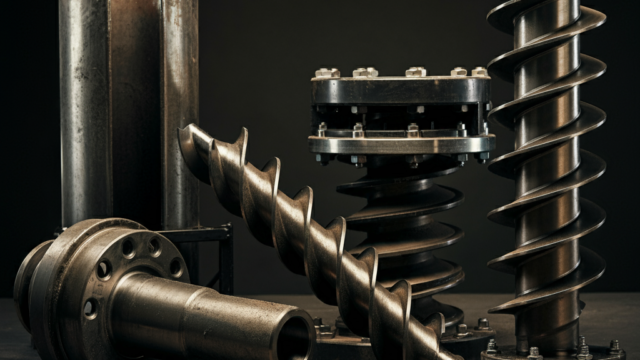

The Importance of the Angle of Repose in Screw Feeders

When choosing a screw feeder as a powder feeder, the angle of repose is an essential factor. Powders with a large angle of repose tend to have poor flowability and are more likely to clog inside the screw feeder, requiring an appropriate feeder design. Conversely, powders with a small angle of repose have better flowability, enabling smoother transport, but excessive flowability can lead to issues with stable feeding, which might also require countermeasures.

Specifically, when designing a screw feeder, it is necessary to adjust the feeder diameter, screw diameter, pitch, rotation speed, and hopper shape based on the powder’s angle of repose. By optimizing the structure and operation of the feeder with reference to the angle of repose data, it is possible to prevent clogging and fluctuations in the feed rate, ensuring stable volumetric feeding.

Relationship with Hopper Discharge Angle

The angle of repose of a powder is also closely related to the design of powder storage equipment, such as hoppers and silos. In particular, the discharge angle of the hopper (the hopper’s tilt angle) is critical for ensuring the smooth flow of powder. Whether the powder stored inside the hopper flows out smoothly is significantly influenced by the hopper’s angle and the powder’s angle of repose.

If the discharge angle of the hopper is smaller than the powder’s angle of repose, the powder may not flow smoothly, and a phenomenon called “bridging” could occur inside the hopper. Bridging happens when the powder aggregates at the hopper’s opening, stopping the flow.

On the other hand, if the discharge angle of the hopper is sufficiently larger than the angle of repose, the powder will naturally flow more easily, reducing the chance of clogging. Therefore, in hopper design, it is crucial to set the discharge angle appropriately based on the powder’s angle of repose.

To prevent bridging, several methods can be employed, such as using agitators (bridge breakers) inside the hopper to loosen the powder, installing vibrators to shake the powder loose, or using knockers to provide impact that breaks up the aggregated powder. Each method has its pros and cons, so it is important to choose the right one based on the powder’s characteristics.

Key Design Considerations:

- Measuring the Angle of Repose: Measure the angle of repose to understand the powder’s characteristics and assess its flowability.

- Setting the Hopper Discharge Angle: Ensure that the discharge angle is larger than the angle of repose to facilitate the smooth flow of powder. Our standard hoppers are designed with a 60° discharge angle, which covers most needs.

- Utilizing Auxiliary Devices: For powders with a large angle of repose and low flowability, consider installing agitators, vibrators, or aeration devices in the hopper to improve flow.

- Coordination with the Screw Feeder: Optimize the interaction between the hopper and the screw feeder to ensure stable powder feeding.

Conclusion:

The angle of repose and the discharge angle of the hopper are closely related to efficient powder transportation. By accurately understanding the angle of repose and designing the hopper’s discharge angle accordingly, clogging can be prevented, enabling efficient operation of transportation devices such as screw feeders.

Just like the angle of repose another important piece of information is bulk density.

You can find an article about it here ↓