1.The Necessity of Space-Saving Screw Feeders

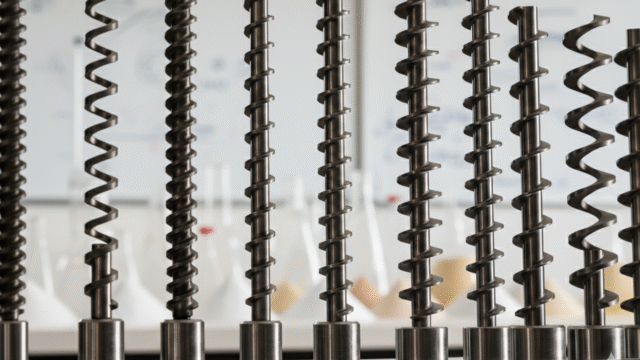

In recent years, production lines in factories have been required to not only increase efficiency but also make the most of limited space. Particularly in urban areas or when installing manufacturing lines within existing facilities, space constraints significantly impact productivity and equipment selection. In response to this, space-saving designs in machinery and equipment are gaining attention, and screw feeders are no exception. Traditional large-scale supply devices often take up too much space, potentially disrupting the layout and workflow of the entire factory. As a result, the demand for compactly designed screw feeders is increasing.

2.Benefits of Space-Saving Screw Feeders

There are several key benefits to introducing compact screw feeders. First, it allows for more efficient placement in limited spaces, increasing the flexibility of the production line. Space-saving screw feeders are easy to install and do not require extra space when integrating with existing equipment. This reduces costs associated with changes to the overall factory layout or additional foundation work.

Second, maintenance becomes easier. Compact screw feeders often provide easier access, reducing the time required for maintenance tasks. Equipment that is easy to maintain contributes to reducing downtime, ultimately improving production efficiency.

Additionally, space-saving screw feeders lead to improved energy efficiency. Due to their smaller size, they require less power, contributing to lower running costs. This helps reduce long-term operating expenses and supports a more sustainable manufacturing process.

3.Case Study: Chemical Factory Facing Space Constraints

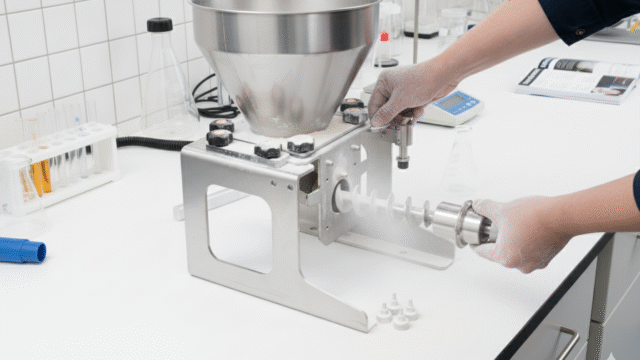

A chemical factory aiming to increase production needed to introduce a new powder supply device. However, the existing facility had only limited space, making it difficult to install a large supply machine. Therefore, they decided to introduce a space-saving screw feeder.

In this factory, the conventional screw feeder posed space problems, preventing the operation of multiple lines and limiting production capacity. However, with the introduction of the compact screw feeder, they were able to efficiently install it in the limited space and add additional lines while maintaining the existing ones. As a result, production capacity was significantly improved, and the factory was able to increase its total output.

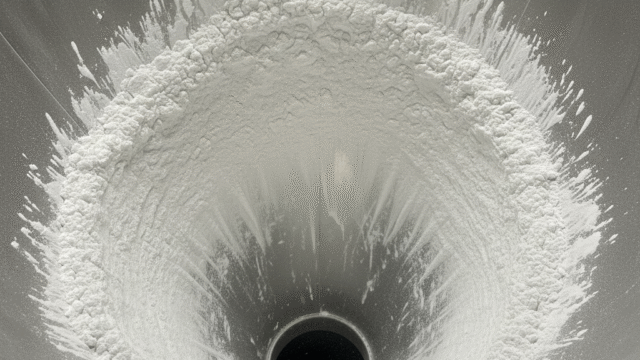

Moreover, the factory achieved improvements in the stability and accuracy of powder supply. Despite its compact design, the screw feeder maintained precision, ensuring uniformity in the product and achieving great results in quality control. Furthermore, the reduced maintenance burden led to less downtime, boosting overall production efficiency.

4.Considerations for Introducing Compact Screw Feeders

When introducing compact screw feeders, there are a few considerations to keep in mind. First, it is crucial to ensure that the design does not sacrifice performance, such as processing capacity or supply accuracy, due to the smaller size. There may be cases where miniaturization leads to insufficient supply volume or reduced powder flowability, so it is recommended to conduct thorough simulations and testing before introduction.

Additionally, the design should be tailored to the environmental conditions of the installation site. Factors like the type of powder, humidity, and temperature can impact the internal structure and material selection of the feeder. By applying appropriate materials or coatings, stable operation over the long term can be achieved.

5.Conclusion

Space-saving screw feeders enable efficient operation in limited factory space, contributing significantly to improving production efficiency and reducing costs. When introducing them, it is important to select the appropriate feeder while considering performance and environmental conditions. As demonstrated by successful cases, compact screw feeders provide a powerful solution for maintaining high productivity, even in confined spaces.