In recent years, the global demand for screw feeders has been increasing across various industries. From food and pharmaceuticals to chemicals and battery materials, more factories are seeking reliable and accurate powder feeding solutions. This growing need is being driven by several key trends in manufacturing and material handling.

1. Increasing Demand for Precision Powder Feeding

Many production processes today require high levels of accuracy when handling powders. Whether it’s small-scale lab tests or high-volume production lines, the ability to feed a precise amount of powder consistently is essential. Screw feeders are ideal for this task because they provide stable and repeatable discharge rates, helping manufacturers improve product quality and reduce waste.

2. Automation and Labor Shortages

As more factories shift toward automation, equipment that can operate with minimal human input becomes increasingly valuable. Powder feeders like screw-type feeders can be integrated into automated systems, reducing the need for manual powder handling. This is particularly important in regions facing labor shortages or high labor costs.

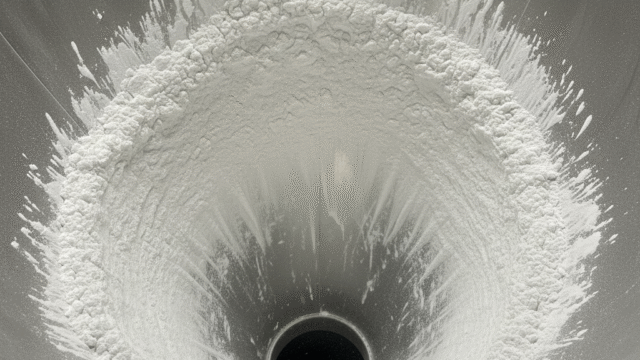

3. Safe and Clean Powder Handling

Screw feeders also offer improved safety and hygiene. Because powder is enclosed in a controlled system, there is less dust generation, which contributes to a safer and cleaner working environment. In industries such as pharmaceuticals and food, where hygiene is critical, this is a major benefit.

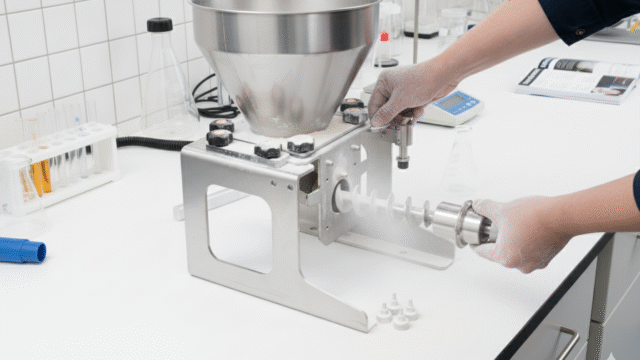

4. Customization and Compact Design

Another reason behind the popularity of screw feeders is their versatility. Custom-made models can be designed to handle various types of powders — from free-flowing to cohesive materials. Compact, bench-top feeders are also in high demand for research laboratories and pilot plants where space is limited but performance must remain high.

5. Global Shift Toward Smaller Batch Production

With the rise of personalized products and frequent product changeovers, many factories are moving away from mass production toward smaller batch manufacturing. This shift increases the need for flexible powder feeding systems that can be quickly cleaned and adjusted. Small screw feeders meet these demands effectively, making them a preferred choice in modern production environments.

If you’re looking for a compact and customizable screw feeder that offers reliable powder feeding performance, feel free to contact us. Our feeders are designed with flexibility, cleanliness, and precision in mind — ideal for today’s evolving manufacturing needs.

VISIT OUR WEBSITE