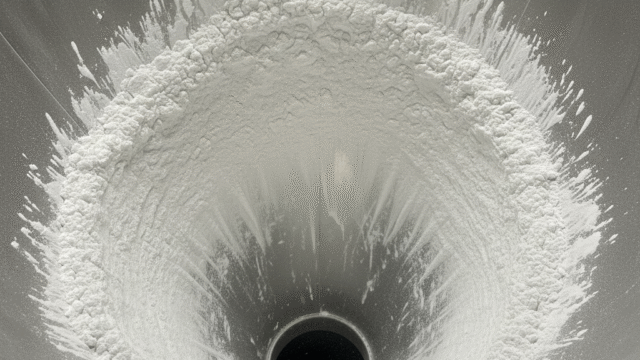

1️⃣ The Persistent “Bridging” Problem in Powder Handling

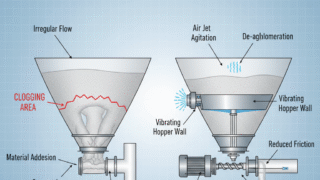

In powder conveying and weighing systems, one of the most common issues is bridging,

where powder forms an arch inside the hopper and stops flowing.

This leads to production stoppages, inaccurate dosing, and inconsistent product quality—

especially when handling fine or slightly moist powders.

2️⃣ Why Bridging Occurs

・Powder tends to agglomerate due to static electricity or humidity

・The hopper angle is too shallow, reducing flowability

・Powder is compressed after long residence time

・Material adheres easily to the hopper wall

When these conditions overlap, powder bridges across the hopper outlet, blocking the flow completely.

3️⃣Main Solutions for Bridging

①Agitator

The most common and reliable solution is the agitator—a rotating blade installed inside the hopper.

It gently breaks up powder buildup and maintains a stable downward flow toward the screw feeder.

Seiwa Giken’s screw feeders are equipped with an agitator located at the bottom of the hopper.

It rotates at an optimized speed that prevents bridging without disturbing the screw feeding motion.

In addition, all powder-contact parts are polished, minimizing powder adhesion and buildup.

② Knocker

A knocker periodically strikes the hopper wall using pneumatic force.

It’s highly effective for powders that tend to stick or absorb moisture.

Because it acts externally, it helps dislodge adhered material without contaminating the powder.

③ Vibrator

A vibrator transmits fine vibration to the entire hopper, promoting powder movement.

It works well with high bulk density or uneven particle size materials.

However, excessive vibration may over-fluidize the powder, so adjusting the position and intensity is crucial.

4️⃣ How Seiwa Giken Applies These Solutions

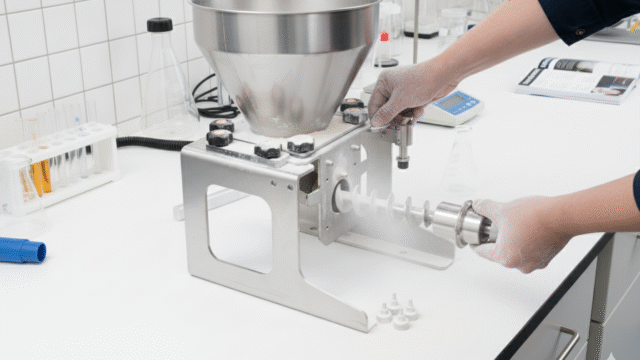

MIni screw feeder

Equipped with both an agitator and an air vibrator,

this model ensures stable discharge even with cohesive or moisture-prone powders.

Standard Screw Feeder (20L Hopper Type)

Equipped with both an agitator and an air vibrator,

this model ensures stable discharge even with cohesive or moisture-prone powders.

Conclusion

Effective bridging prevention requires a combination of methods tailored to the powder’s characteristics.

Seiwa Giken designs each screw feeder with an optimal balance of agitator, knocker, and vibrator to maintain a consistent and reliable powder flow.

Every unit can be customized in terms of screw size, pitch, and material to ensure optimal performance for specific powder properties.

👉 Learn more about Seiwa Giken’s Screw Feeders↓↓