Strengthening Worksite Safety Measures – Proposals for Introducing Powder Feeders and Powder Mixers

From the perspective of ensuring safety in factory operations, we would like to introduce common examples of safety measures when implementing our powder feeder “Screw Feeder” and powder mixer “Tumbler Mixer.”

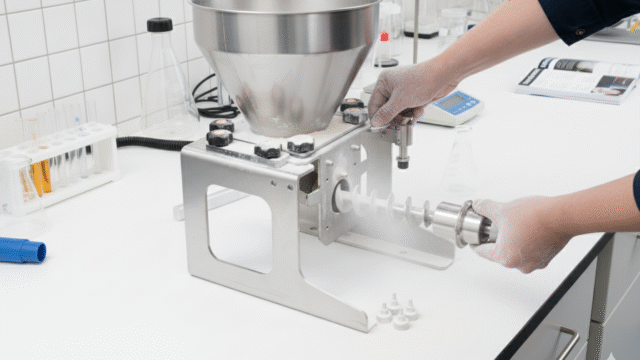

1. Safety Measures When Introducing the Screw Feeder

The screw feeder possesses excellent safety characteristics. Compared to manual work or other conveyance equipment, the screw feeder reduces the risk of exposing workers to hazards during its operation.

Specific Safety Proposals:

- Prevention of Powder Leaks with Enclosed Design:

The screw feeder operates in an enclosed environment, significantly reducing the risk of powder scattering outside. This minimizes the chance of workers coming into direct contact with powders, thereby lowering health risks. It also helps prevent dust generation, ensuring a cleaner and safer work environment. - Installation of Interlocks:

Interlocks can be installed on the hopper and maintenance cover of the screw feeder. This ensures that the machine automatically stops when the cover is opened, preventing workers from accidentally touching the machinery while it is operating. This is essential for ensuring safety during maintenance. - Accident Prevention with Proximity Sensors:

If a worker gets too close to the operating feeder, proximity sensors will trigger an alarm or automatically stop the machine. This reduces the risk of workers inadvertently entering hazardous areas, enhancing overall safety management.

Benefits of Introduction:

- Ensures worker safety while maintaining production line efficiency.

- Enclosed transport prevents powder scattering, maintaining a clean work environment.

- Interlocks and sensors help prevent accidents before they occur.

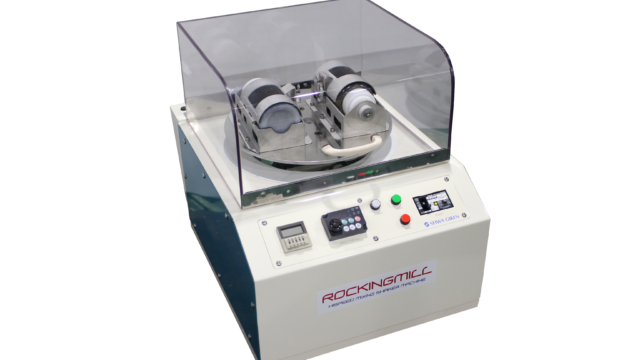

2. Safe and Efficient Powder Mixing with the Tumbler Mixer

To enhance worker safety during powder mixing operations, protective measures such as safety fences are required when using the “Tumbler Mixer.” Equipping the mixer with interlocks that prevent the front door from being opened during operation ensures safety. Additionally, safety devices can be customized to meet each company’s safety standards.

Specific Safety Proposals:

- Safety Fence and Interlock Functionality:

Installing safety fences on all four sides of the mixer and adding an interlock function that stops the machine when the front door is opened will prevent operational errors during mixing. This ensures that workers are not accidentally exposed to the inside of the mixer. In recent years, more companies are requiring interlocks that prevent the front door from being opened while the machine is running. The tumbler mixer comes standard with electromagnetic locking interlocks for the front door of the safety fence. - Optimizing the Height and Placement of Safety Fences:

Safety fences should be installed at a sufficient distance around the tumbler mixer, designed to prevent workers from easily climbing over or reaching into the machine. For easy maintenance and inspection, control panels should be positioned outside the fences to ensure operational efficiency without compromising safety.

Benefits of Introduction:

- The safety fence and front-door interlock functions significantly reduce the risk of operational errors and accidents during mixing.

- Increased production efficiency combined with a safer work environment reduces the risk of occupational accidents.

3. Points to Consider When Introducing the Equipment

To further enhance safety and efficiency when introducing equipment, consider the following points:

- Customization Based on Work Environment:

Our screw feeders and tumbler mixers can be customized to fit your specific work environment. Whether you have space constraints or need equipment tailored to the characteristics of the powder being handled, we can adapt to meet your needs. We also comply with strict safety standards set by your company, ensuring optimal safety when introducing our equipment. - Regular Maintenance and Inspection:

To ensure the correct functioning of safety features, regular maintenance and inspections are essential. Our products come with user manuals that clearly outline periodic inspection methods and guidelines for replacing consumable parts. - Enhancing Worker Training:

Even after equipment is introduced, worker education is necessary to ensure that operators correctly use the equipment and fully utilize its safety features. We provide training during installation and offer advice on safety measures, helping to raise safety awareness among workers.

4. Conclusion

Our “Screw Feeder” and “Tumbler Mixer” are not just tools for improving production efficiency, but they are also key partners in safeguarding worker safety. Safety is not limited to preventing injuries. By maintaining an enclosed environment for powder materials and utilizing interlock-equipped devices, we contribute to the overall safety of the worksite, preventing accidents and protecting workers’ health.

PLEASE VISIT OUR WEBSITE