Moisture Control and Prevention of Solidification in the Screw Feeder

Powders easily absorb moisture, and when stored or handled in humid environments, they may solidify or stick together, making handling difficult. This can reduce work efficiency and affect product quality. In this article, we will explain how to address moisture issues when operating our products, such as the powder supply machine “Screw Feeder,” powder conveyor “Air Suction Loader,” and powder mixer “Tumbler Mixer.”

Moisture Control and Prevention of Solidification in the Screw Feeder

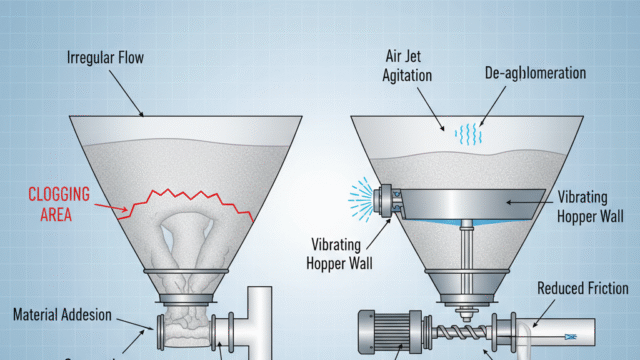

The screw feeder is used to supply powder, but when powder sticks due to moisture, it causes unstable supply, affecting the amount being fed. To prevent this, it is important to manage both the environment where the screw feeder is installed and the powder itself.

First, thorough humidity control in the location where the screw feeder is installed is essential. For example, introducing air conditioning or dehumidifiers to maintain a constant temperature and humidity around the feeder helps create an environment where the powder is less likely to absorb moisture. Additionally, nitrogen purging in contact areas within the hopper or feeder can be a useful technique to prevent powder from absorbing moisture.

In cases where the powder tends to stick, regularly cleaning and maintaining the screw feeder can prevent clogging and feeding failures, ensuring a smooth supply.

Moisture Prevention During Powder Conveyance with the Air Suction Loader

The air suction loader is a device that transports powder using airflow. However, in humid environments, there is a higher risk of the powder solidifying during conveyance. To reduce this risk, it is crucial to manage the humidity inside the pipes and the suction area of the air suction loader.

To prevent moisture from entering the pipes of the air suction loader, it is necessary to control the environment where the raw materials are stored. Instead of a suction method where the nozzle is directly inserted into open paper bags, it is better to store the raw material in a hopper first, sealing it to prevent moisture absorption, and then connecting a hose for automatic suction. Improving the sealing performance of the entire conveyance route also prevents external moisture from infiltrating.

Moreover, adjusting the conveyance speed and feed rate can shorten the time the powder stays inside the pipes, minimizing the risk of moisture absorption.

Moisture Control in the Tumbler Mixer

The tumbler mixer is used to uniformly mix powder. However, if moisture enters during mixing, the powder may solidify, reducing mixing efficiency and causing defects in the mixture. To prevent this, it is crucial that the powder is sufficiently dried before mixing and that the environment inside the mixing container is kept dry.

The container used in the tumbler mixer is a commercially available stainless steel tank with high sealing capability. When loading raw materials, it is important to manage the indoor air conditioning to avoid moisture during the loading process. By maintaining a moisture-free environment, the powder can be prevented from absorbing moisture during mixing, ensuring uniform mixing. Additionally, controlling the humidity in the work area is vital to prevent powder solidification.

When extracting the mixed powder, it is also important to create as sealed an environment as possible to prevent external moisture from entering, thereby minimizing the influence of the external environment. Particularly in cases where frequent opening and closing are required during mixing, managing the humidity of the entire work area is crucial.

Conclusion

Powder’s tendency to absorb moisture leads to solidification and sticking, making handling difficult. However, by properly managing the environment, this risk can be significantly reduced. By controlling the humidity during feeding with a screw feeder, preventing moisture during transport with an air suction loader, and managing humidity during mixing with a tumbler mixer, you can maintain powder quality and improve work efficiency.

Preventing moisture absorption is essential to creating an environment where powders can be easily handled and their quality maintained. Through thorough humidity control, the introduction of drying systems, and proper maintenance, it becomes possible to handle powders in an optimal state.

PLEASE VISIT OUR WEBSITE