The Introduction of Powder Filling Machines Significantly Contributes to Stable Product Quality and Reducing Waste

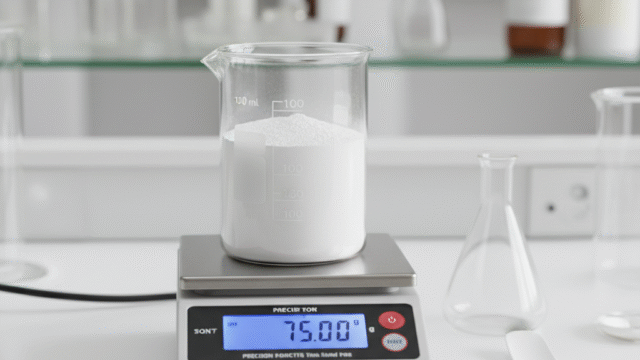

In industries such as food, chemicals, and pharmaceuticals, where accurate measurement and precise filling of powders are critical, issues like human filling errors, variations in filling amounts, and differences in operator speed can greatly impact production efficiency and costs. To address these challenges, the use of a screw feeder-based weighing and filling system can significantly improve both accuracy and operational efficiency.

1. Features of Screw Feeders and Their Impact on Weighing Accuracy

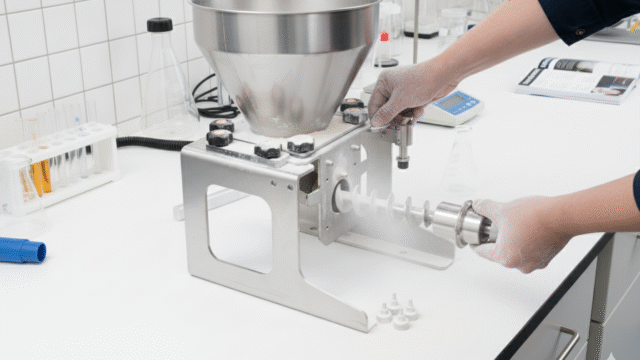

A screw feeder is a device that supplies powder using a rotating screw, enabling the powder to be dispensed in precise amounts. By incorporating this device into the filling process, weighing accuracy is improved, and operator errors or variations in filling times are minimized.

- Mechanism of Constant Supply: The screw rotates to supply a fixed amount of powder each time. The rotation speed can be finely controlled using an inverter, allowing for adjustments according to the target filling amount to ensure precise filling. Particularly when high weighing accuracy is required, manual operations that rely on the operator monitoring the scales can be time-consuming and dependent on the operator’s skill level. However, with a screw feeder, consistent time and accuracy are maintained regardless of who is operating the machine.

- Adjustment Features: Not only can the screw feeder’s rotation speed be controlled, but the shape and size of the screw can also be selected. Using an optimal screw based on the characteristics of the powder ensures that the powder maintains its flowability while being supplied with high accuracy.

2. Benefits of Weighing and Filling with a Screw Feeder

Compared to traditional manual or simple filling methods, using a screw feeder offers several advantages:

- Reduction of Filling Errors: The screw feeder’s weighing and filling system accurately dispenses the pre-set amount, minimizing human error. This significantly reduces waste and loss during the filling process.

- Increased Efficiency: Since the machine handles the weighing process, the burden on the operator is significantly reduced, improving the overall production speed. This is especially important in mass production, where it is crucial to balance both precision and speed. A screw feeder achieves both.

- Prevention of Powder Scattering: The screw feeder supplies powder through a sealed pathway, minimizing the risk of powder scattering and maintaining a clean work environment. This also improves product quality control and the health management of operators.

3. Specific Improvements to Enhance Filling Accuracy

To maximize the accuracy of the powder filling process using a screw feeder, the following improvements should be implemented:

- Introduction of Feedback Control: By integrating a load cell with the screw feeder, a feedback control system can be implemented. This system measures the weight in real time during filling, allowing for precise adjustments, such as slowing down the screw rotation just before reaching the target weight. This prevents over- or under-filling and ensures consistent accuracy.

- Adoption of Step-Filling Method: Dividing the screw feeder’s filling process into two stages, “fast filling” and “slow filling,” enhances accuracy. The bulk of the powder is first filled quickly, and the remaining small amount is adjusted at a slower speed, allowing for efficient operation without over- or under-filling.

- Optimization of Screw Design: The shape and pitch of the screw should be adjusted based on the nature of the powder being filled. For example, a wider pitch screw can prevent clogging in powders with low flowability, while a narrower pitch screw can ensure stability in powders with high flowability.

4. Maintenance and Operational Points for Screw Feeders

Proper maintenance and operation are essential to maintaining accuracy in screw feeders.

- Regular Cleaning and Inspection: Since powders tend to remain in certain parts of the screw feeder, regular cleaning is necessary. Particularly when handling different types of powders, thorough cleaning of the interior is crucial to prevent residual powders from mixing.

- Replacement of Worn Parts: Over time, parts of the screw and weighing components may wear down, leading to reduced accuracy. Regular inspections and part replacements will help maintain consistently high accuracy.

Conclusion

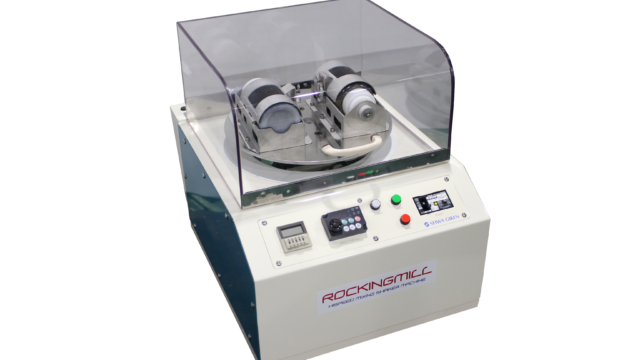

Weighing and filling systems that utilize screw feeders are being introduced in a wide range of industries, including the food, chemical, and pharmaceutical sectors. In addition to performing weighing tasks on their own, screw feeders also assist in ensuring stable supply to other machines (such as grinders and vibrating sieves), preventing issues like processing failures, clogging, and solidification.

Whether in the chemical, food, or pharmaceutical industry, the introduction of screw feeder-based weighing and filling machines ensures consistent filling amounts for each product, allowing users to provide consistently high-quality products.

Moreover, reducing the burden on operators and ensuring safety makes the shift from manual operations to screw feeders increasingly popular in recent years.

PLEASE VISIT OUR WEBSITE