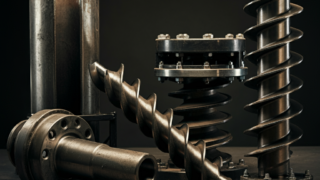

In factories, foreign material contamination is a serious issue that directly affects product quality and undermines trust. Particularly in processes involving powders, it can be challenging to completely prevent contamination due to the nature and flowability of the powders. However, by introducing an appropriate powder supply system and incorporating certain improvements, it is possible to significantly reduce the risk of contamination. This article introduces ways to prevent contamination, focusing on systems that use screw feeders.

1.Introducing Sealed Screw Feeders

A fundamental measure to prevent contamination is to introduce sealed screw feeders. When the powder supply process has many open sections, the risk of foreign materials entering from outside increases. Sealed screw feeders minimize external influences, preventing dust or tiny particles from entering the supply line and ensuring a stable supply.

2.Material Selection and Surface Treatment of Feeders

The material and surface treatment of screw feeders are crucial for preventing contamination. If the supplied powder contains metal components like stainless steel, using materials that are corrosion-resistant and highly wear-resistant can prevent rust and metal fragments from mixing in. Additionally, smooth surface treatments make it harder for powder to stick to the feeder, reducing the risk of contamination buildup.

3.Design for Ease of Cleaningaterial Selection and Surface Treatment of Feeders

Regular cleaning is essential to prevent contamination. Therefore, screw feeders should be designed for easy disassembly and internal cleaning. In industries like food and pharmaceuticals, which have strict hygiene standards, features such as quick-release mechanisms that allow disassembly without tools, and designs that allow thorough cleaning, are recommended. This not only prevents contamination but also ensures consistent product quality.

4.Utilizing Air Filters and Dust Collectors

Dust and fine particles generated during powder supply can also be sources of contamination. Installing air filters or dust collectors around screw feeders helps capture dust in the air, removing potential contamination sources. In clean rooms or environments requiring high cleanliness, such equipment is essential.

4.Introducing Magnet Traps and Metal Detectors

Metal fragments are one of the most problematic types of foreign materials in powder supply systems. To mitigate this risk, it is common to incorporate magnet traps and metal detectors in screw feeders. Magnet traps effectively capture metal fragments such as iron or stainless steel that enter the supply line, preventing contamination. Metal detectors can identify non-ferrous metals and other metallic foreign materials, greatly reducing the risk of contamination.

5.Operator Education and Strengthening Management Processes

Preventing contamination requires not only system improvements but also operator education and process management. Contamination can often result from the working environment or how operators handle the equipment. Regular training is necessary to reinforce correct handling methods and the importance of cleaning and inspection in minimizing contamination risks. Additionally, setting up a system to quickly address contamination issues when they arise can help prevent problems from escalating.

6.Conclusion

To prevent foreign material contamination, it is essential to implement multiple countermeasures in the design and operation of powder supply systems centered around screw feeders. Through sealed designs, appropriate material selection, easy-to-clean features, and the introduction of filters and magnet traps, the risk of contamination can be significantly reduced. Additionally, operator education and enhanced management processes contribute greatly to preventing contamination. By combining these measures, you can supply high-quality products consistently and maintain customer trust.are parts availability. Please make use of our expertise and technology to solve your powder supply challenges.a safe working environment is a vital investment that leads to improved productivity and sustainable growth for the company