In modern manufacturing, product diversification has advanced, leading to a wide variety of powder types and sizes. To efficiently and stably supply these diverse powders, screw feeders must offer flexible adaptability. This article explains the key points to consider when handling powders of different sizes and how to select the most suitable screw feeder.

1. Issues Caused by Different Powder Sizes

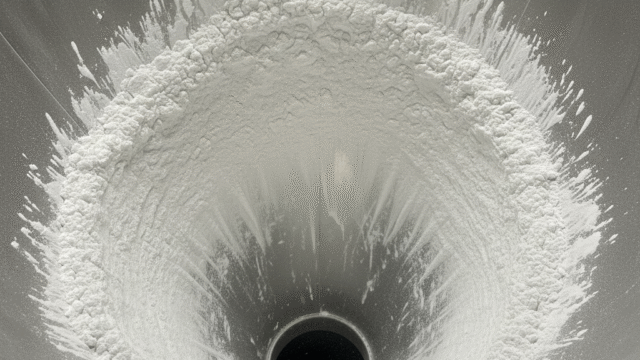

When powder sizes vary, their behavior inside the feeder changes, making uniform supply difficult. For example, fine powders have low flowability and tend to clump inside the feeder, leading to clogging. On the other hand, coarse powders may flow excessively, resulting in unstable feed rates. This can lead to product quality inconsistencies and reduced production efficiency.

2. Key Points for Selecting a Screw Feeder

To ensure smooth feeding of powders of different sizes, it is essential to select the appropriate screw feeder. By focusing on the following points, efficient powder feeding can be achieved:

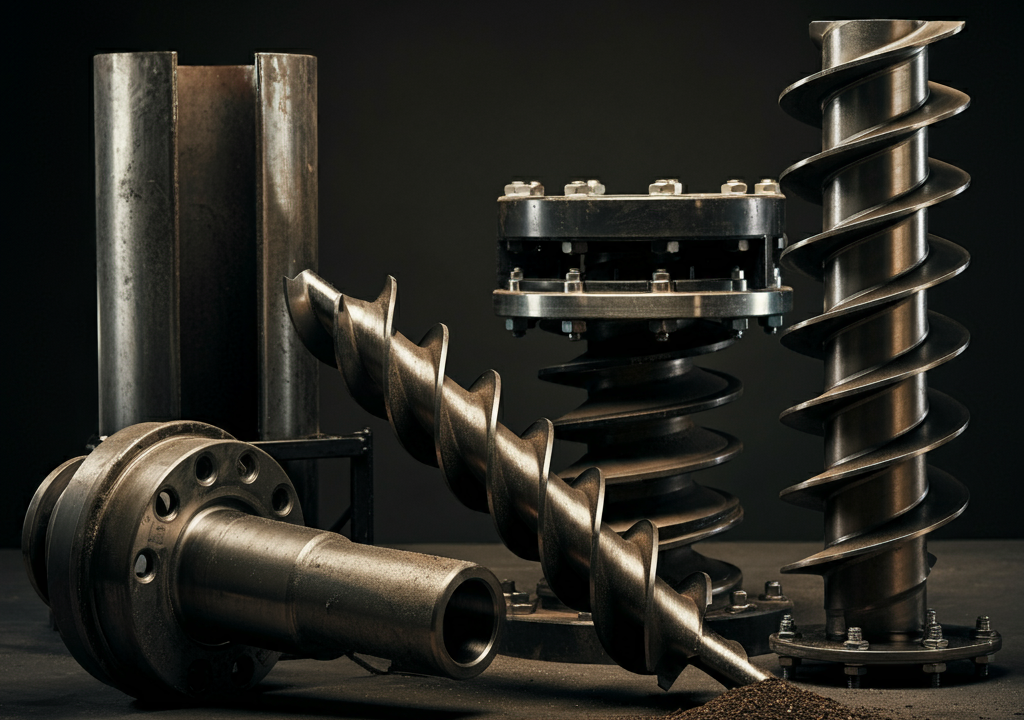

- Screw Design Selection The shape of the screw includes variations such as pitch width and blade angle. We generally recommend the standard screw with equal pitch, which is highly versatile and suitable for various powder materials. For higher precision or low-output applications, a double-start screw is ideal, while for sticky or highly viscous materials, a shaftless screw is effective.

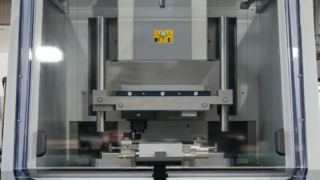

- Variable Speed Control Adjusting the feeding speed is necessary when powder sizes vary. By equipping the feeder with variable speed control, you can adjust the speed according to the powder type, ensuring stable feeding.

- Feeder Size Selection It is also important to select the appropriate screw feeder diameter and feed port size based on the desired output rate. Larger diameters are generally for high-output applications, while smaller diameters focus on precision.

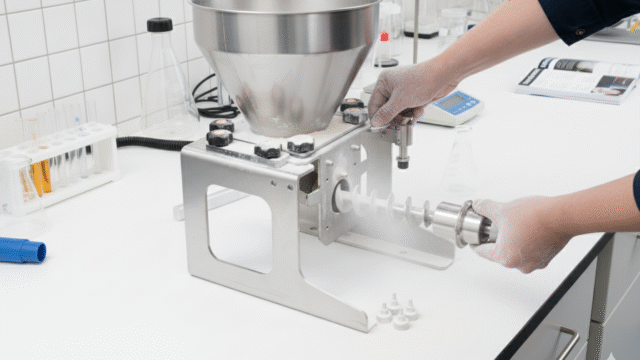

3. Maintenance and Adaptability for Different Powders

When frequently handling powders of varying sizes, the maintenance of the feeder becomes a significant challenge. Regular cleaning and maintenance to prevent contamination are essential. Selecting a screw feeder that can be easily disassembled and cleaned minimizes downtime. Additionally, modular feeder designs that allow easy replacement of screws and parts enhance flexibility in handling different powders.

4. Conclusion

When using powders of different sizes, the selection and adjustment of the screw feeder are crucial. By considering screw design, feed speed control functions, and ease of maintenance, you can build an efficient production line. This will stabilize product quality and improve factory productivity. The introduction of flexible screw feeders capable of handling powders of different sizes will become increasingly important in future manufacturing. By selecting the right equipment, long-term production efficiency and cost savings can be achieved.line. Regular maintenance and inspections are essential to ensure these measures function correctly at all times.