Optimizing Screw Feeder Control for Precise Powder Feeding

In industries where precise powder feeding is critical, screw feeders play an indispensable role. Proper control of a screw feeder not only ensures consistent material flow but also prevents common issues like pulsation, clogging, and inaccurate dosing. This article dives into the fundamentals of screw feeder control, exploring key factors and techniques to achieve stable and efficient powder feeding.

What is a Screw Feeder?

A screw feeder is a mechanical device designed to transport and meter powders or granular materials at controlled rates. It consists of a rotating screw housed inside a tube or trough, where the screw’s rotation moves the material forward. This simple yet effective mechanism is widely used in pharmaceutical, food processing, chemical, and other industries requiring accurate powder handling.

Importance of Precise Powder Feeding

Accurate powder feeding is vital for maintaining product quality and process efficiency. Irregular feeding can cause batch inconsistencies, equipment downtime, and material waste. Therefore, controlling the screw feeder’s speed and ensuring stable powder flow is essential for optimal operation.

Factors Affecting Screw Feeder Control

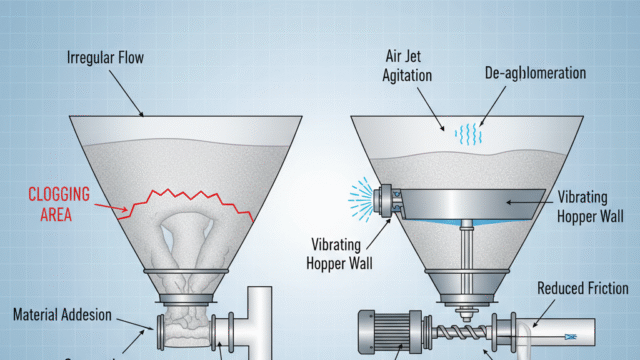

Several factors influence the performance of screw feeders:

- Screw Speed Control: The feeder’s rotation speed directly affects the powder feed rate. Using variable speed drives allows fine-tuning to meet specific process requirements.

- Powder Characteristics: Particle size, bulk density, moisture content, and flowability impact how powders behave during feeding.

- Feed Rate Consistency: To minimize pulsation and flow interruption, steady rotation and proper screw design are crucial.

- Feeder Design: Screw geometry, pitch, diameter, and trough shape all affect feeding accuracy and efficiency.

- Environmental Conditions: Temperature and humidity can influence powder flow and may require adjustments in feeder control.

Techniques for Stable Screw Feeder Operation

To enhance screw feeder control and powder feeding stability, consider the following approaches:

- Variable Frequency Drives (VFDs): These devices allow smooth adjustment of screw rotation speed, providing precise feed rate control.

- Closed-Loop Feedback Systems: Incorporating load cells or weighers enables real-time monitoring and automatic adjustments to maintain target feed rates.

- Anti-Pulsation Designs: Implementing double-screw or specially shaped screws reduces pulsation and improves uniform powder flow.

- Proper Powder Conditioning: Pre-treating powders to improve flowability can enhance feeder performance.

- Regular Maintenance: Keeping the screw and trough clean prevents material build-up and blockages.

Applications of Screw Feeders in Powder Feeding

Screw feeders are utilized across many sectors for powder feeding tasks:

- Pharmaceuticals: Metering active ingredients with high precision.

- Food Industry: Feeding flour, sugar, spices in production lines.

- Chemical Manufacturing: Controlled addition of catalysts or powders.

- Plastics: Feeding polymer powders for molding processes.

Conclusion

Mastering screw feeder control is key to achieving precise, stable, and efficient powder feeding. By understanding the interplay between feeder design, powder properties, and control technologies like VFDs and feedback systems, manufacturers can optimize their processes and ensure product quality. Whether in pharmaceuticals, food, or chemicals, well-controlled screw feeders contribute significantly to operational success.g challenges with quantitative powder supply, feel free to contact us.

PLEASE VISIT OUR WEBSITE