What is Powder Coating? Powder coating is a solid paint that does not contain solvents and is primarily applied using electrostatic powder coating or fluidized bed coating methods. Since it has a low environmental impact and does not emit volatile organic compounds (VOCs) compared to solvent-based coatings, it has been widely adopted in recent years, especially as environmental regulations become stricter. Additionally, powder coating offers excellent adhesion and durability, making it suitable for applications in various fields, including automotive parts, home appliances, and construction materials.

Challenges of Powder Coating While powder coating has numerous advantages, there are also challenges in handling it. Being in powder form, it is highly susceptible to moisture absorption, which may affect its coating performance depending on storage conditions and handling methods. Additionally, blending different types of powder coatings uniformly is not an easy task, as there is a risk of color inconsistencies and quality variations. Therefore, an appropriate mixing technology is essential.

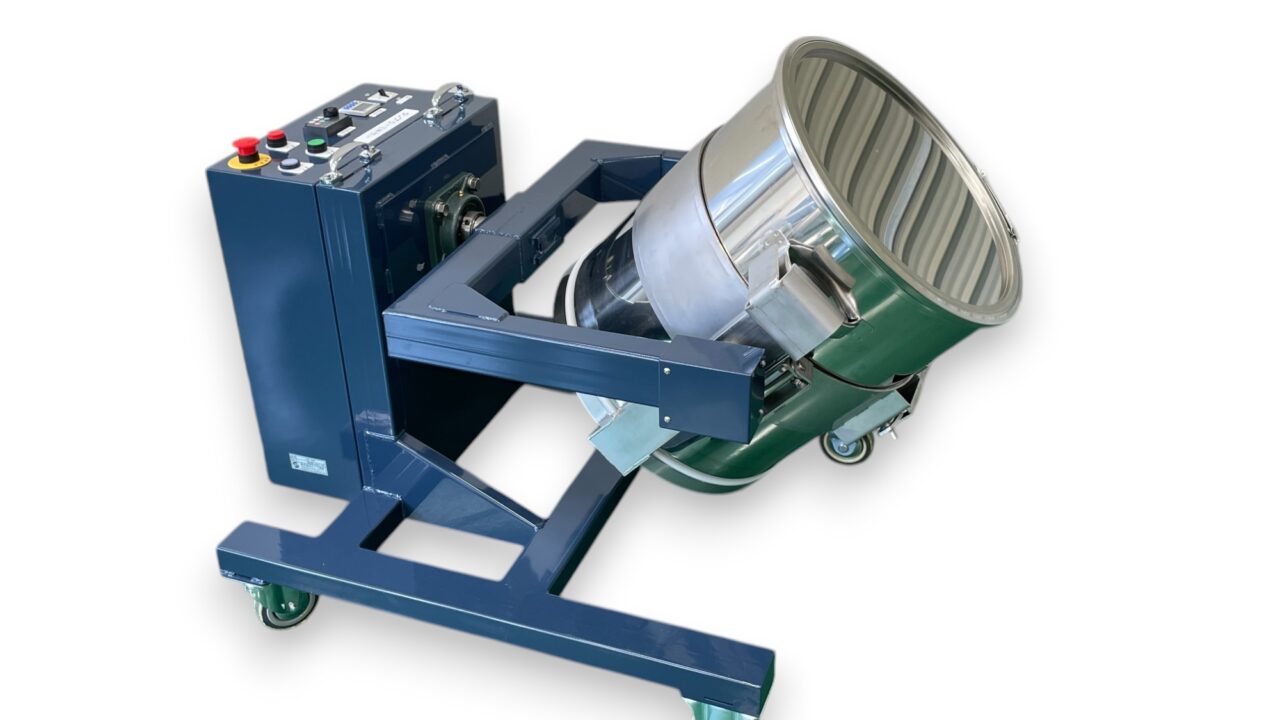

The Role of the Tumbler Mixer Seiwa Giken’s tumbler mixer is a device developed to efficiently mix powder coatings. This mixer adopts a method where the container itself rotates, allowing for uniform blending without compromising the properties of the powder. It is particularly suitable for industries that require stable quality, as it can mix even delicate powder coatings while minimizing particle breakage and aggregation.

Features of the Tumbler Mixer Seiwa Giken’s tumbler mixer offers the following features:

- Uniform Mixing: The entire container rotates, enabling the internal powder to flow naturally and mix thoroughly, ensuring a uniform blend.

- Minimal Damage to the Powder: Since no paddles or stirring mechanisms are used, particle breakage and static electricity generation are minimized.

- Improved Work Environment: Mixing occurs within a sealed container, preventing dust dispersion and reducing health risks for workers.

- Versatile Applications: In addition to powder coatings, it can be used in industries such as pharmaceuticals, food, and ceramics.

Conclusion Proper management and uniform mixing of powder coatings are essential for achieving high-quality coatings. By utilizing Seiwa Giken’s tumbler mixer, challenges related to powder coating blending can be overcome, ensuring stable and consistent coating quality. As environmental regulations become stricter, adopting powder coatings and appropriate mixing technologies is crucial for establishing a sustainable manufacturing process.gies are driving market growth. Moving forward, further innovations are expected to bolster sustainable manufacturing practices and enhance the role of powder mixers in a variety of applications.