Powder handling equipment often struggles with powder sticking to hopper walls, leading to unstable flow and inconsistent feeding.

Materials with high moisture absorption, fine particle size, or slight oil content tend to show increased build-up, especially under small environmental changes.

This article explains key design points for minimizing powder adhesion and ensuring stable discharge.

1. Optimize hopper angle and geometry

The geometry of a hopper significantly influences powder flow behavior.

- Use steeper wall angles (commonly 60° or more)

- Prefer smooth, curved transitions

- Avoid excessively narrow discharge sections

Poor-flowing powders are highly prone to bridging and ratholing in shallow-angle hoppers, resulting in build-up and residual material on the walls.

2. Improve surface finish to reduce adhesion

One major cause of powder sticking is surface roughness.

Common countermeasures include:

- Mirror polishing

- Non-stick coatings (e.g., fluoropolymer)

- Material selection, such as switching from SUS304 to SUS316L

Reducing the friction coefficient helps powders slide more smoothly and significantly reduces wall residue.

3. Use vibration or air-assist to support flow

If adhesion cannot be avoided through geometry alone, mechanical or pneumatic support can help.

- Vibrators for controlled shaking

- Air purging to reduce sticking

- Automatic tapping mechanisms around the hopper exterior

Note: Excessive vibration can worsen bridging, so adjusting the intensity is important.

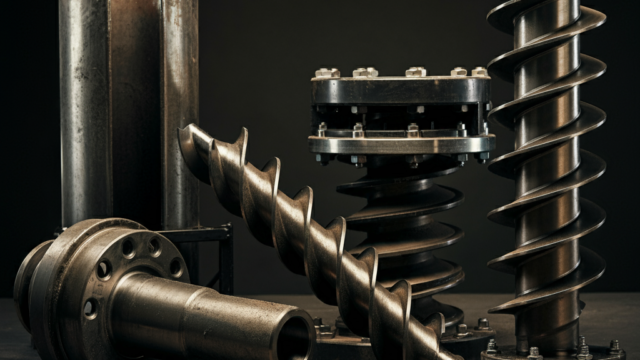

4. Combine with a screw feeder for stable discharge

A hopper alone cannot eliminate build-up entirely.

Pairing the hopper with a screw feeder can dramatically improve discharge stability.

Benefits include:

- Screw rotation continuously breaks material tendencies to bridge

- Various screw shapes (including conical types) can handle cohesive powders

- Stable feeding even with difficult materials

Optimizing screw shape and speed based on powder characteristics minimizes the influence of adhesion.

5. Understanding powder characteristics is the most effective countermeasure

Effective anti-build-up design begins with understanding material properties:

- Adhesiveness

- Moisture absorption

- Particle size distribution

- Shape (spherical / irregular)

- Oil content

These factors determine which hopper structures, finishes, and screw configurations will work best.

About Seiwa Giken

Seiwa Giken provides Mini Screw Feeders and Standard Screw Feeders designed to handle powders with varying flowability and adhesion characteristics.

Through testing and evaluation, we help users identify optimal feeding conditions—even for materials that are difficult to handle.

👉 Learn more about Seiwa Giken’s Screw Feeders↓↓