Preventing Powder Blockage Without Agitator Blades: A Case Study Using a Screw Feeder and Air Vibrator

One of our customers approached us with the following issue:

“We’re working with a low-flowability powder that tends to clog in the hopper. However, due to contamination concerns, we cannot use any internal agitator blades.”

Blockages inside hoppers are a common challenge in powder feeding. Materials that are fine, cohesive, or have low bulk density often cause problems like bridging (where powder arches over and blocks flow) or rat-holing (where only the center empties, leaving powder stuck on the sides).

A typical solution involves installing an agitator blade inside the hopper to break up the powder. However, for processes where foreign matter must be strictly avoided—such as in food, pharmaceutical, or clean-room applications—using mechanical agitators may not be an option. Some users also prefer simpler hopper structures to improve cleanability and reduce maintenance needs.

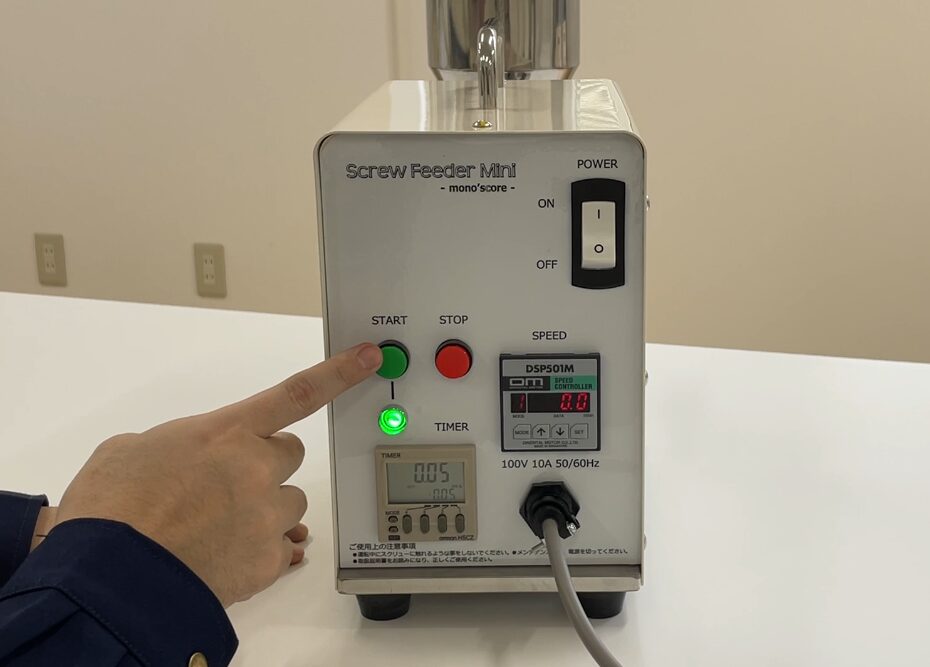

In such cases, we often recommend a combination of a screw feeder and an air vibrator as a non-contact solution.

How an Air Vibrator Helps Keep Powder Flowing

An air vibrator is a small device that generates vibration using compressed air. When mounted on the outside of a hopper, it delivers subtle shaking to the hopper walls, which helps prevent powder bridging and rat-holing.

Unlike agitator blades, an air vibrator does not touch the powder directly, minimizing the risk of contamination. This setup allows powders to fall smoothly into the screw feeder without adding internal moving parts.

The result is a simple yet effective system that improves flow without compromising cleanliness or structure.

Effective for a Wide Range of Challenging Powders

This screw feeder + air vibrator combination has proven especially effective for:

・Fine powders such as silica or carbon black

・Lightweight materials like resin powder or cellulose

・Hygroscopic powders such as starch or powdered milk

Many customers report smoother discharge and more stable operation after implementing this approach.

Conclusion: A Clean and Simple Solution Without Agitation Blades

If you’re dealing with powder bridging but can’t use internal agitators due to contamination concerns or structural simplicity, this method may be the ideal fit.Combining a screw feeder with an air vibrator offers a practical, clean, and reliable solution for consistent powder feeding—even with difficult materials.Feel free to contact us if you’d like to explore this solution for your process.