Screw feeders are used as powder feeders and are used in a variety of industries and processes.

The following are examples of the main uses of screw feeders.

Material Feeding in Manufacturing: Screw feeders are used in the manufacturing industry to efficiently feed raw or powdered materials to production lines. For example, they are used to feed raw materials in the food processing industry or in chemical processes.

Metallurgy and mining: Screw feeders are also used to feed ores and crushed ores into metallurgical processes.

Building materials production: Screw feeders are used to feed materials evenly in production lines for building materials such as cement, gypsum, and sand.

Chemical processes: In the chemical industry, screw feeders are used to feed powder materials for powder mixing and reactions.

Plastics manufacturing: In plastics manufacturing, screw feeders are also used to feed powder and granular raw materials to injection molding machines.

Food Industry: In food processing lines, screw feeders are used to precisely feed powdered seasonings and ingredients.

Environmental Technology: Screw feeders are also applied to effectively process certain powdered materials in waste treatment and recycling processes.

These are common examples; usage varies by industry and process. Screw feeders serve to improve production efficiency and product quality by feeding powder materials at a constant rate and in a controlled manner.

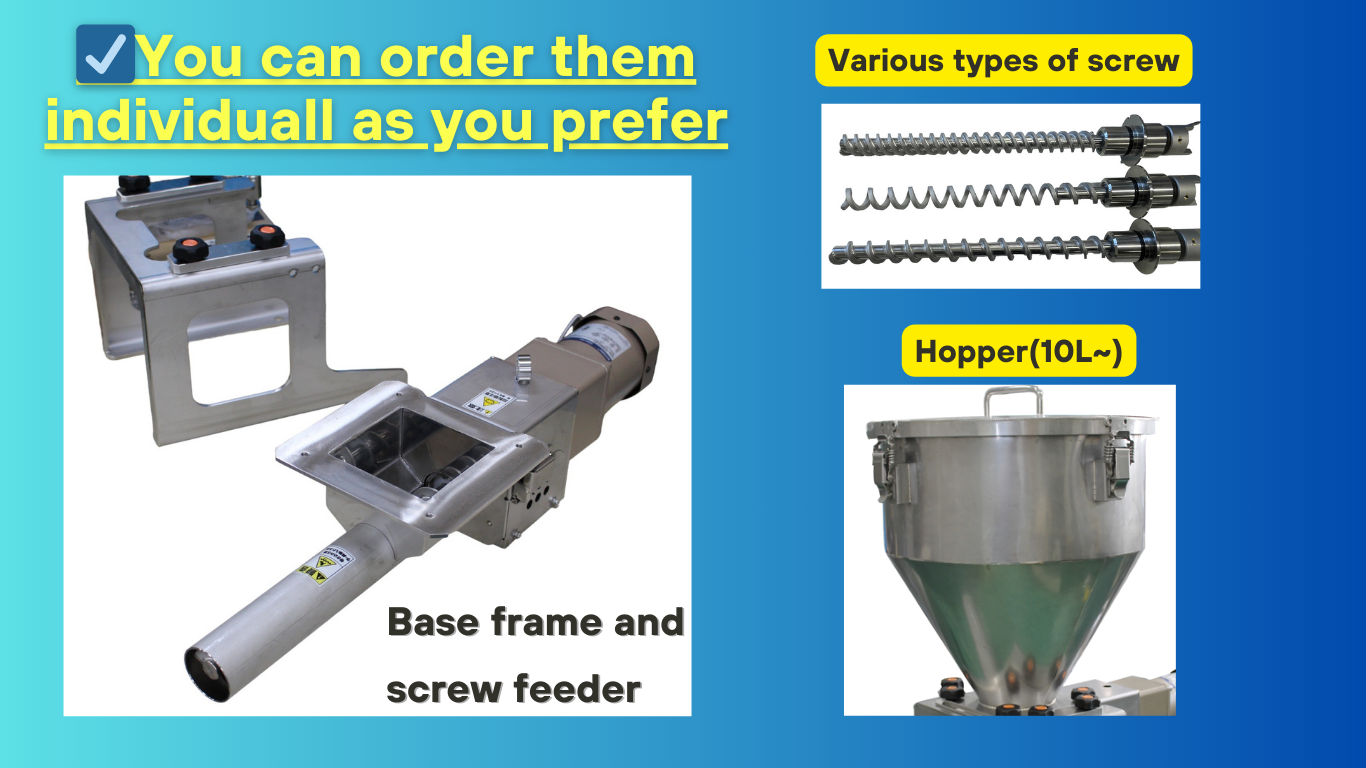

We design, manufacture, and sell screw feeders that meet various raw material and discharge capacities required by customers. In addition to the main unit, screw feeders often include a hopper for storing raw materials, an agitator to prevent bridging, and a control panel.

The hopper can be used in a wide variety of ways, such as using the one currently in use, incorporating it into one of the manufacturing processes, or using it for experiments and tests. We can design and manufacture hoppers to meet your needs, so please feel free to contact us.