Our mini rotary valves for powders are valves specifically designed to control the flow of powder and granular solid materials. These valves are widely used in a variety of industries and are particularly important for the accurate metering and feeding of materials. The features, applications, advantages and disadvantages of mini rotary valves for powders are described below.

Main features

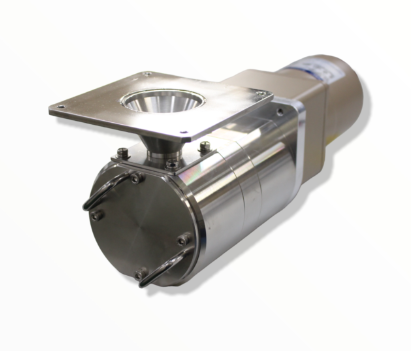

1:Construction

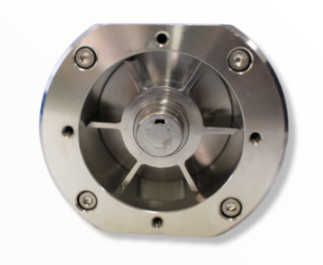

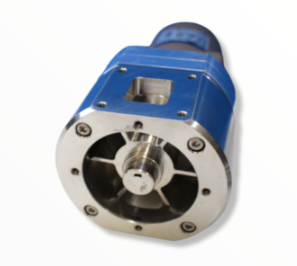

The rotary section usually consists of a rotating cylinder with multiple pockets, which is designed to allow only a specific amount of powder to flow at a time.

It consists of a valve body, rotor, seal and drive mechanism (manual or automatic).

2:Operation

As the rotor rotates, the powder enters the rotor pocket from the upper hopper and is further discharged into the outlet at the bottom.

The speed of rotation can be controlled to regulate the powder feed rate.

3:Material

Wear-resistant materials (e.g. stainless steel, aluminium, polymers) are used.

Depending on the properties of the powder (e.g. corrosive, abrasive, adhesive, etc.), the appropriate material is selected.

4:Size and shape

Small, lightweight and compact design.

Easy to integrate into powder handling systems.

Main applications

1:Chemical industry

Used for weighing and dosing chemicals and raw materials.

2:Food processing

Used to feed powdered materials such as sugar, flour and cocoa.

3:Pharmaceutical industry

Used for the accurate weighing and feeding of pharmaceutical ingredients.

4:Construction materials

Used to supply powder materials such as cement and gypsum.

Advantages

High accuracy: accurate weighing and dosing of powders is possible.

Quick operation: the powder feed can be adjusted in a short time.

Durable: by choosing the right materials, they are resistant to abrasion and corrosion.

Compact: can be installed in small spaces.

Disadvantages

Cost: due to their high-precision design, they may cost more than other types of valve.

Maintenance: due to the nature of the powder, adhesion and blockages can occur and regular maintenance is required.

Small rotary valves for powder applications play an important role in many industries where accurate powder flow control is required. Efficient powder handling can be achieved by selecting and using the right valve.

We manufacture small rotary valves from the unique perspective of a powder feeder manufacturer. If you are interested, please do not hesitate to contact us.