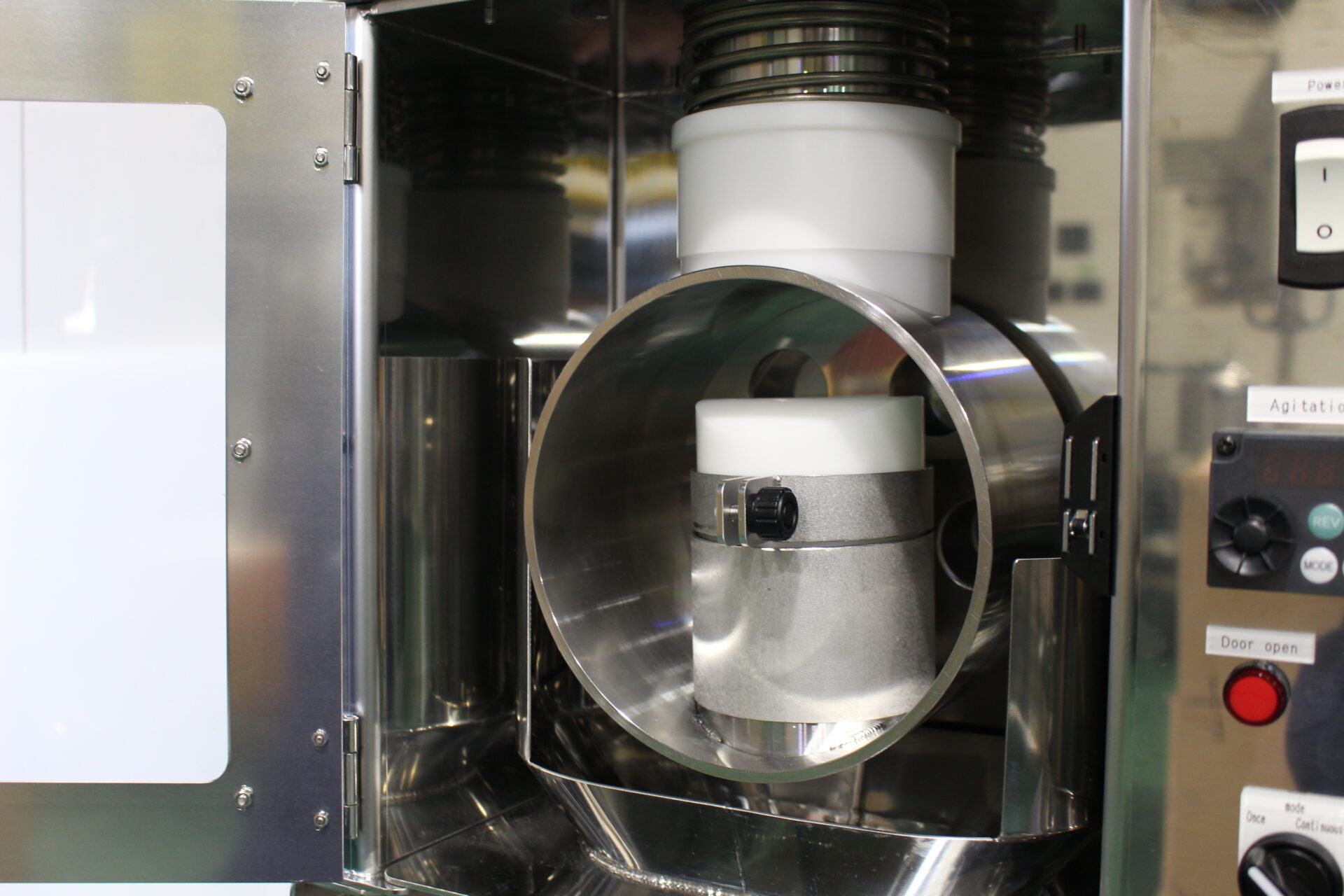

Case study:Volumetric Cup Filler,a simple and Flexible Powder Filling Solution for the Food Industry

A volumetric cup filler is a simple yet highly effective powder filling machine that uses fixed-volume cups to dispense powders and granular materials with consistent accuracy. Unlike screw feeders or load cell-based systems, volumetric filling systems rely purely on the physical volume of the cup to control the amount of product dispensed.

Easily Adjustable Filling Volume

One of the key advantages of our volumetric cup filler is its adjustable filling capacity. By simply changing the vertical position of the cup, operators can increase or decrease the volume without the need to replace parts or reprogram settings.

・Raising the cup reduces the filling volume

・Lowering the cup increases the filling volume

This intuitive design makes it ideal for food manufacturers that frequently switch between different product sizes or batch requirements.

Accurate and Stable Powder Dosing

This system offers reliable and repeatable dosing for a wide variety of powders and granules, such as:

・Flour and sugar

・Coffee grounds and tea powders

・Spices and seasonings

・Cereal products

・Nutritional supplements and functional food ingredients

As a food-grade powder filling solution, it’s designed for easy cleaning and hygienic operation, suitable for both large-scale production and small-batch filling.

Compact Design with Proven Track Record in the USA

Our compact powder filler requires minimal space and is easy to install on a tabletop or integrate into existing production lines. Several units have already been successfully installed by food manufacturers in the United States, where it’s been praised as a reliable and low-maintenance volumetric powder filler.

Applications Across Industries

This system is used in a wide range of industries, including:

・Food and beverage (instant mixes, seasonings, powdered drinks)

・Health supplements (protein powders, vitamin blends)

・Cosmetics and personal care (powdered ingredients in sample packaging)

・R&D and pilot plants (small-batch product development)

Conclusion

If you’re looking for a cost-effective, easy-to-operate, and space-saving powder dosing system, our volumetric cup filler offers a practical solution with a strong performance record—both in Japan and in the U.S. market. Its simple volume adjustment mechanism and consistent powder filling accuracy make it a perfect fit for manufacturers seeking to streamline their production processes.