The screw feeder of SEIWA GIKEN

A screw feeder is a device that discharges various powders and raw materials by rotating a spiral screw mounted inside a pipe.

By changing the size of the screw (diameter, winding pitch, etc.), the discharge volume can be adjusted, and by changing the shape of the screw, it is possible to transport raw materials according to their characteristics (smoothness and fluidity, adhesiveness and cohesiveness, fluffy and light, etc.). Screw feeders are one of the most stable conveying methods because they can handle a wide variety of powders.

Screw feeders can stably feed a fixed amount of powdered raw material by rotating a screw at an even pitch, but care must be taken to ensure that a fixed amount is metered.

Generally, there are two types of screw feeders (fixed quantity screw feeders and metering screw feeders).

Advantages ・Fewer pieces of equipment are required and costs are lower.

Disadvantages ・The error range varies depending on the type of powdered raw material and discharge conditions.

In the case of volumetric screw feeders, the discharge volume is determined by the pitch of the screw, and is not actually weighed by a scale, but as long as the raw material in the screw feeder is constant, a stable amount can be continuously discharged.

However, if you want to weigh a fixed amount, such as 500 g or 1 kg, simply stopping at a certain time will not eliminate the error.

Also, as the remaining volume in the hopper decreases, the discharge volume also changes due to changes in the applied pressure.

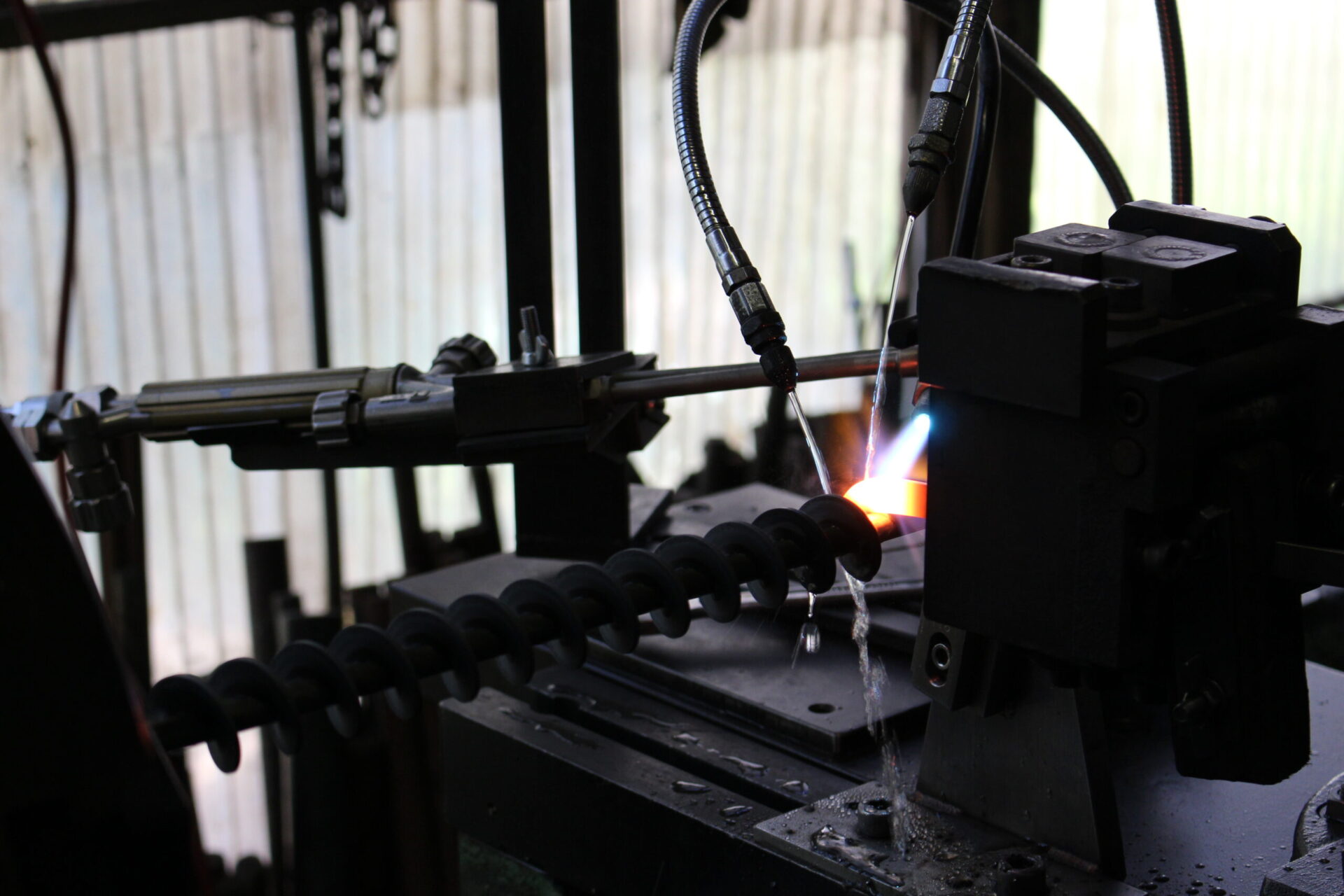

The shape and size of the screw are selected according to the characteristics of the powdered raw material and the discharge volume.The material is generally stainless steel SUS304, and surface treatment is selected according to the operating environment.

There are various types of screws generally used, including screws carefully wound one by one by craftsmen and special screws machined on state-of-the-art multi-axis lathes.

In addition, all welding parts that come in contact with powder are standardized to be all-around welding, eliminating the risk of contamination from powder remaining in the crevices.

We deliver safe screws that can be used with confidence in all industries.