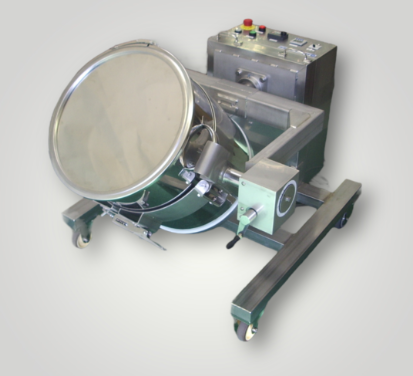

Commercial tanks can be converted directly into mixing containers!

Rotating vessel type mixer for complete mixing without damaging powdered materials

| Model | TMH-65(TMHS-65) |

|---|---|

| Applicable container | 10L,15L,20L,25L,36L,45L,65L(NITTO METAL INDUSTRY, Stainless Steel Hermetic Containers) |

| Loading capacity | Max. 40 kg or less |

| Input amount | 50-60% of total tank volume recommended |

| Vessel rotation speed | Max. 45 rpm (at 60 Hz inverter setting) |

| Mixing time | Up to 15 minutes (*Timer setting) |

| Material | Body exterior SUS304 SS coating and SUS304 are available for the main frame |

| Optional function | Safety fence /Elevating lifter |

| External dimensions | (W)870×(D)1080×(H)735mm |

| Input voltage | Single phase AC100V or three phase 200V |

| Total weight | 95kg |

Examples of Supported Materials

Chemicals (General)

Silica, Talc, Alumina, Ceramics, Slaked Lime, Activated Carbon (Granules, Powder), Carbon Granules, Graphite, Glass Powder, Pigments, Zinc, Manganese Dioxide, Potassium Carbonate, Calcium Carbonate, Light Anhydrous Silica, Aluminum Oxide, Magnesium Oxide, Ammonium Phosphate, Titanium Oxide, Silica Sand, Soil, Feed, Water Purification Agents, Coagulants, Preservatives, Ion Exchange Resin, Cement, Kenaf, Glycerin, Boron Nitride, Incineration Ash, Pigments, Soap, Bath Additives

Biomass & Carbon Neutral

Wood Pellets, Wood Chips (Sawdust), Rice Husks

Resins & Fibers

Pellets, Masterbatch, Resin Powder, Crushed Resin Material, Resin Flakes

Metals

Iron Powder, Various Metal Powders

Food

Flour, Soy Flour, Salt, Sugar, Soybean Powder, Coffee Powder, Tea Powder, Protein Powder, Powdered Dressing, Rice, Rice Flour, Citric Acid, Baking Soda