Characteristics of materials

We have manufactured a wide variety of screw feeders to suit a wide variety of materials.

・Material that flows smoothly like sand in an hourglass

・Material that contains water and is moist like salt

・Material similar to potato starch that hardens when squeezed.

At Seiwa Giken, we are developing equipment and taking measures to realize quantitative transport even for materials with various characteristics like this.

What is powder bridging?

This is one of the phenomena that tends to occur with materials with poor fluidity. The material does not flow well from the material hopper to the blade gap of the screw feeder, and the material is not discharged quantitatively or not at all. If it enters the inlet of the screw feeder from the hopper, it will be clogged.

What substances can cause this phenomenon?

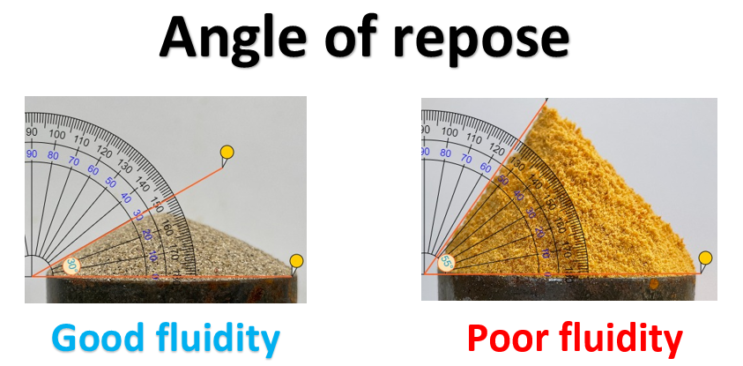

We check material shape, bulk density, angle of repose, cohesiveness, etc. The most obvious is the angle of repose. The higher this height is, the more likely it is that it will not flow smoothly like sand ⇒ bridging will occur.

Cohesiveness also has a significant impact on bridging. Materials that tend to harden when gripped do not collapse in the hopper and do not flow to the entrance of the screw feeder.

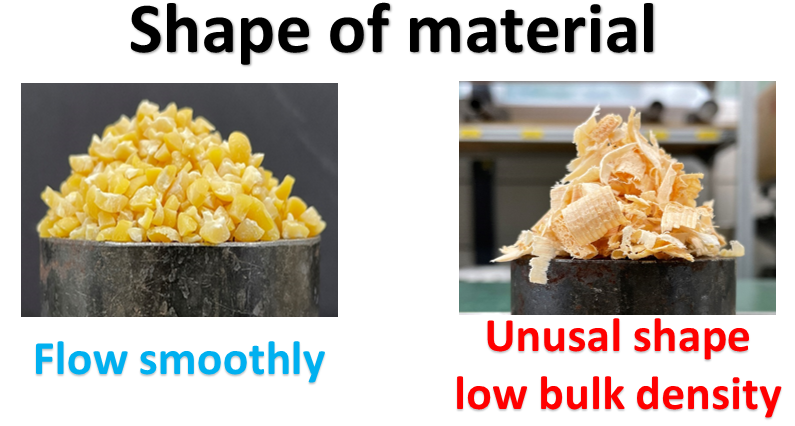

Bridging may also occur if the material has a low bulk density and does not fall off under its own weight, or if it has a special shape such as a fiber.

Each powdered raw material has its own characteristics.

We identify the cause of bridging through pre-testing and take countermeasures. We will explain the specific method in the next column.