How is a screw feeder for powder most frequently used for?

Screw feeders are frequently used for the fixed-quantity feeding of powder materials, but what kind of situation do you imagine when you want to feed powder materials in a fixed-quantity?It may be a little difficult for some people to imagine, since they rarely see this equipment in their daily lives, but let us introduce an actual production example.

A confectionery store told us, “It is very difficult to manually weigh dozens of kilograms of sugar every day!We want a equipment that can weigh out XYZ kg in about XYZ seconds with the touch of a button!”We helped them to solve this problem by manufacturing a screw feeder that can feed the desired amount of sugar in a timely manner.

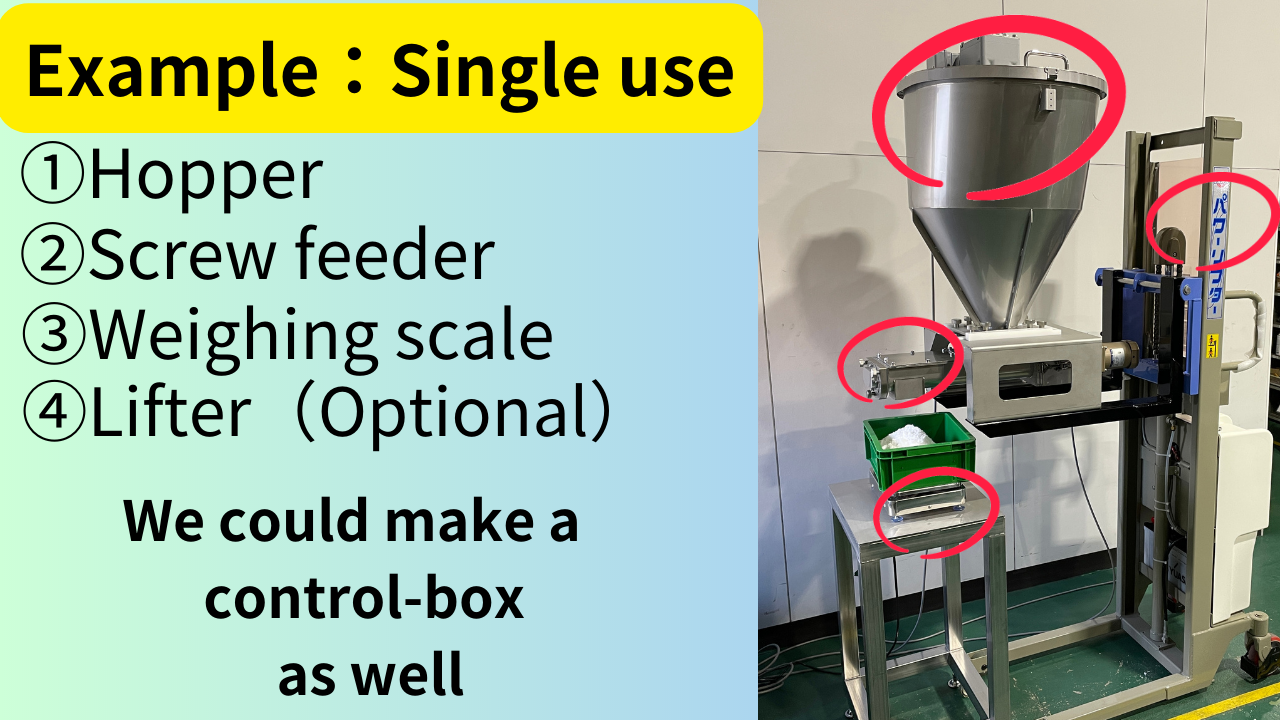

This is an actual example of using a screw feeder as a stand-alone unit. Material is fed into the hopper, weighed and discharged according to the desired amount & time ⇒ The material that comes out will be carried by hand and used in the next process. The height of the discharge port can be adjusted with a lifter (optional equipment).

In addition to these examples, there is a pattern in which the machine is incorporated between processes in a factory.

For example, “I want to convey this C material from point A to point B at a rate of XYZg/minute.This is also a definite fixed-quantity feeding. In this case, since machines and equipment are already installed at points A and B in many cases, the request will inevitably be to combine the specifications with these machines and equipment.

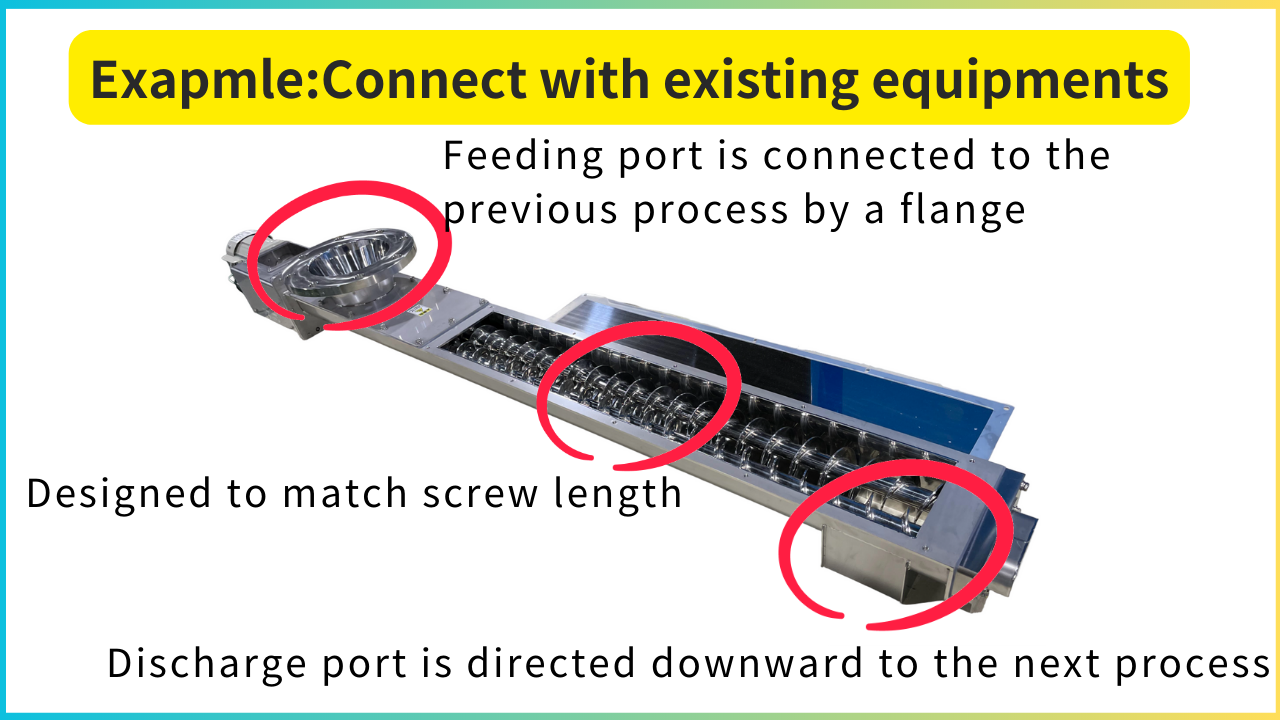

This is a twin-shaft screw feeder, manufactured in accordance with the request.

In order to connect to the equipment in the previous process, the feed port was designed to be flanged, and the discharge port was designed to face downwards to suit the subsequent process. In addition, the distance between the AB process and the length of the screw was also designed to match the distance between the AB process and the discharge port.

When set between facilities in this way, there will always be restrictions on height, length, etc. to connect with the previous and subsequent processes. Even when used as a stand-alone unit, we can customize the design to meet your needs, such as making it easier for the operator to handle.

We hope this has given you some idea of what the screw feeder can do. If you have any questions, please feel free to contact us.