Optional fuction for high accuracy

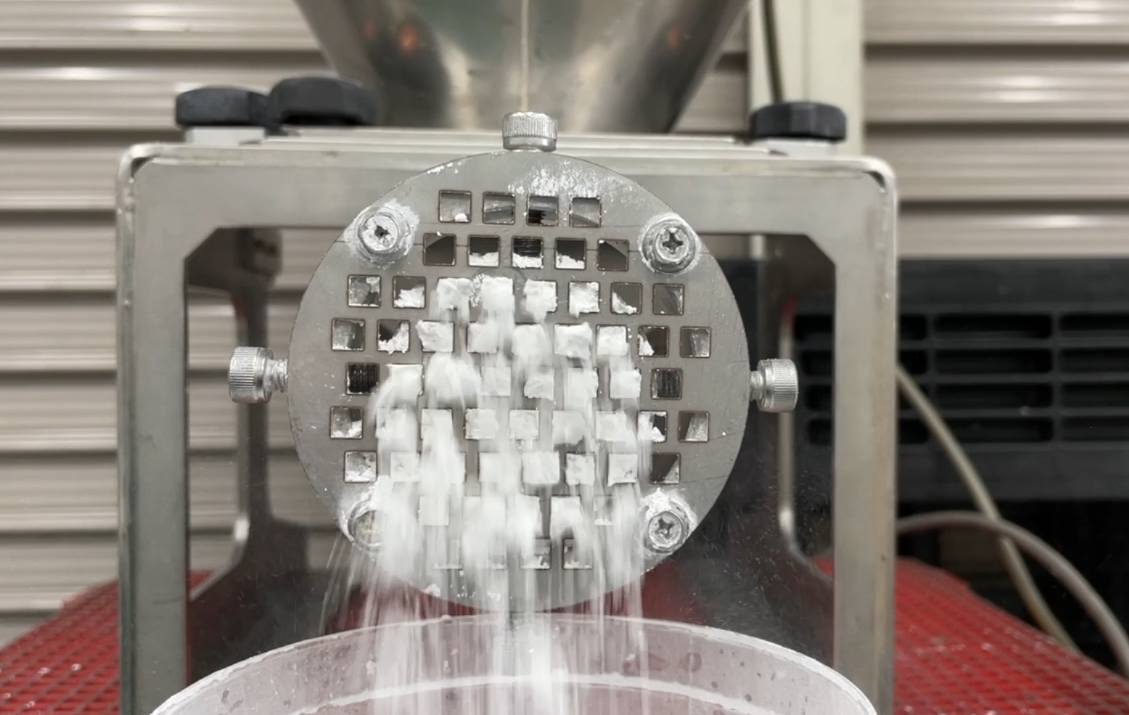

The screw feeders manufactured by our company are mainly used for conveying powders and raw materials. There are many raw materials in the world, each with different characteristics. For example, when the powder is discharged from the screw feeder, the powder may fall as clumps as shown in this photo. At first glance, it seems to be discharged smoothly, but if you try to weigh it accurately, there seems to be variation in the amount of each time.

In general, the quickest way to increase the accuracy of discharge is to change the control to the metering control method. However, in that case, the cost will be higher than the normal specification. There is an easier and faster way. You can easily and inexpensively solve this problem. The easiest way is to use this component. Can you imagine how this little mesh works so effectively?

In this way the powder is loosened and discharged from this mesh part. As a result, it comes to be discharged stably, leading to improved accuracy. It is a part that can be used simply by fixing it to the tip of the screw feeder with a bolt. Since it can be removed when not needed, it can be used according to the characteristics of each powder and material. This method is just one solution and we know many others from our many years of experience.