SCREW FEEDER FOR POWDERED RAW MATERIALS

Designed for easy hopper removal

imply remove the knobs and slide them off

Coupling that connects the screw to the motor

Snap locks for easy removal.

Feed screw can be easily disassembled and cleaned

by simply removing 4 knobs

Features of Screw feeder

Small and compact

Our screw feeders are not as large as conveyors. However, they do not require a large installation space. We manufacture many of them in sizes that can be placed on a table. They can be easily disassembled without tools and cleaned. This simple machine is easy to operate on a daily basis once you get used to it.

Wide Variety of Sizes

We manufacture a wide range of screw sizes to meet the needs of our customers. There are various types of powders, each with different properties and characteristics. We will listen to your needs and propose the most suitable feeding equipment. With our long experience and manufacturing track record, we promise that we will always be able to meet our customers’ needs.

Bridge Countermeasures

A common problem in powder feeding is bridging. Bridging is a phenomenon in which powder clogs up and becomes difficult to flow. Agitators (agitator blades) are recommended as typical countermeasures. Depending on the type of powder, we also offer air vibrators and knockers. Bridging is a common problem with powdered raw materials, but we can offer the best solution according to the characteristics of those raw materials.

Customized Products

Our strength is the ability to customize and manufacture material handling equipment, such as screw feeders and conveyors, according to the customer’s requirements. Depending on the environment of the factory or laboratory, there are many different places where they can be installed. Please consult with us about height, length, connection method, and anything else. We are not a manufacturer that only makes specific products, but rather we are willing to make custom-made equipment according to your specifications and offer solutions to your problems.

Stainless round hopper

The standard hopper is made of round stainless steel (SUS304).

Outer surface / flange ・ ・ ・ 2B material

Inner surface ・ ・ ・ # 400 Abrasive

Hopper capacity can be selected from 10L to 100L

(20L is standard size)

Optional function

Agitating blades are recommended to prevent bridging.The agitator prevents powder bridging (clogging due to agglomeration of powders) in the hopper and supports quantitative feeding of raw materials. As with the screw, the speed of rotation can be adjusted with an inverter.

Pressure proof specification

Welding flange on tip of feeder to connect with established equipments

Surface polished

O-ring for improvement of sealing

Primary specification

| Control method | Screw rotation speed:Inverter Operating time:Timer |

|---|---|

| Feeder diameter | φ25.4,φ38,φ42.7,φ48.6,φ60.5,φ76.3 |

| Screw type | Normal, Shaftless, Twin screw, Double start |

| Hopper size | 20L(Standard) 10L, 30L, 40L, 50L, 100L |

| Measures for powder bridging | Bridge breaker(Agitator) Mounted on the lid |

| Input voltage | 100V AC Single phase(50/60hz) |

| External dimensions | W418×D630×H700mm ※In case of spec:φ42.7 screw feeder and 20L hopper with bridge breaker |

| Weight | Approx:20kg ※In case of spec:φ42.7 screw feeder and 20L hopper with bridge breaker |

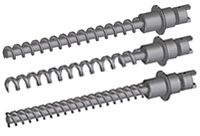

Screws are selected according to powder type and feeding capacity

We offer single-shaft and twin-shaft.

The single-shaft screw is a highly versatile standard specification, while the twin-shaft screw is used for crushing or high precision, depending on the type of raw material. Since this is the most important basic component, we select the optimum one according to the customer’s required specifications.

Single

(Standard/Shaftless/Spring)

Twin

(2N Screw)

| Screw type | Feature | Suitable Powder |

| Standard | The most versatile type | Pellet, Dried powder |

| Shaftless | Prevent adhesion of powder and raw materials | Highly adhesive powder |

| Spring | Feed with high accuracy | Pellet,dried powder |

| Twin(2N screw) | Feed while loosing hard powder | Hard powder |

Amount of feeding pellets(bulk density 0.8) Reference values ※Kg/hour

| Feeder type | φ38 | φ42.7 | φ48.6 | φ60.5 | φ76.3 |

| Standard | 21 | 29 | 73 | 122 | 254 |

| Shaftless | 25 | 34 | 88 | 147 | 304 |

| Spring | 22 | 41 | 80 | 126 | – |

Track records of powder and ingredients

Chemistry

Silica, talc, alumina, ceramic, slaked lime, activated carbon (grains / powder), carbon grains, graphite, glass powder, pigments, zinc, manganese dioxide

Potassium carbonate, calcium carbonate, light anhydrous silicic acid, aluminum oxide, magnesium oxide, ammonium phosphate, silicon dioxide

Chromium trioxide, antimony oxide, cobalt oxide, nickel oxide, bismuth oxide, sodium borate, titanium oxide

Silica sand, soil, feed, water purification agent, flocculant, preservative, ion exchange resin, cement, kenaf, glycerin, boron nitride, incinerated ash

Battery material

Positive electrode material, negative electrode material, conductive auxiliary agent

Biomass carbon neutral

Wood pellets, wood chips (sawdust), rice husks

Resin / fiber

Pellet, masterbatch, resin powder, resin crushing material, resin flakes, PVA resin

Carbon fiber (carbon fiber), PP fiber, crushed glass fiber, acrylic fiber

Metal

Iron powder, iron ore, metal powder (aluminum powder / copper powder) copper ore, cut copper wire

Food

Wheat flour, soybean flour, salt (coarse), salt, granulated sugar, white sugar, soybean flour, black tea flour, powder dressing

Vitamin C, potato starch, buckwheat flour, citric acid, baking soda